Custom EVA Case

Eyewear Cases Factory

At KinFish Case, We Offer Various Custom Options to Create the Outer Shell of Your Branded EVA Cases.

- Lightweight Hard Case

- Waterproof Case

- Durable Zipper

Featured Eyewear Case We Serve

Fully Custom Service

At KinFish Case, we offer a wide range of ways to put your logo on the case shell, zipper, or label, depending on your logo design, your's brand identity, and your budget.

Hard Eva Case Feature

This EVA hard travel case is both stylish and secure, providing water-resistant protection from impact and shock whilst remaining sleek and business-friendly.

EVA Case for Sports & Outdoors

Whether you’re a manufacturer in search of EVA cases to pack and protect your products or sourcing cases in bulk for your business, we offer complete custom solutions for you.

Tailored EVA Case to Match Your Unique Demands

Reach us for custom EVA carrying cases which provide unparalleled protection and storage.

Request A Quote

Talk with us about your rough ideas and custom needs, our case experts will get back to you within 24 hours.

Quality & affordable EVA cases

From A Reliable Factory.

Our in-house manufacturing & 100% inspection make sure that you receive custom EVA cases with consistent and premium quality, and at affordable prices.

In-Depth Design Support

100% Custom Fully Brandable, Stylish Designs & Logo, Custom Color / Shape / Size / Material

Easier to Shape & Low Rejection Rate

With low tooling cost, an EVA foam can be molded to any shape, any size you want.

Low MOQ For Small Order

In 7 days, you will get a prototype of the EVA case and test it for fit, functionality, and durability.

About KinFish Case

Design EVA Cases

Click Video Here

KinFish Case is a custom EVA case manufacturer in China. For KinFish, constructing an EVA case parallels building a house, as both require thoughtful structural design, efficient space utilization, dependable materials, and precise techniques.

KinFish Case is specialized in EVA cases for a wide range market, including consumer electronics, medical supply, outdoor, audio and more. Neoprene cases, plastic zipper cases, backpacks and drawstring bags are offered also. All products are manufactured according to ISO 9001 standard and can be passed Reach, RoHS, SGS and other environmental tests.

Welcome to custom products!

Die Cutting

With over 10 years of molding process, we are able to make your case into any shape as required.

Stitching

Our craftsmen will carefully stitch the different pieces together using a sewing machine. This step ensures that the case is strong and durable.

Customization

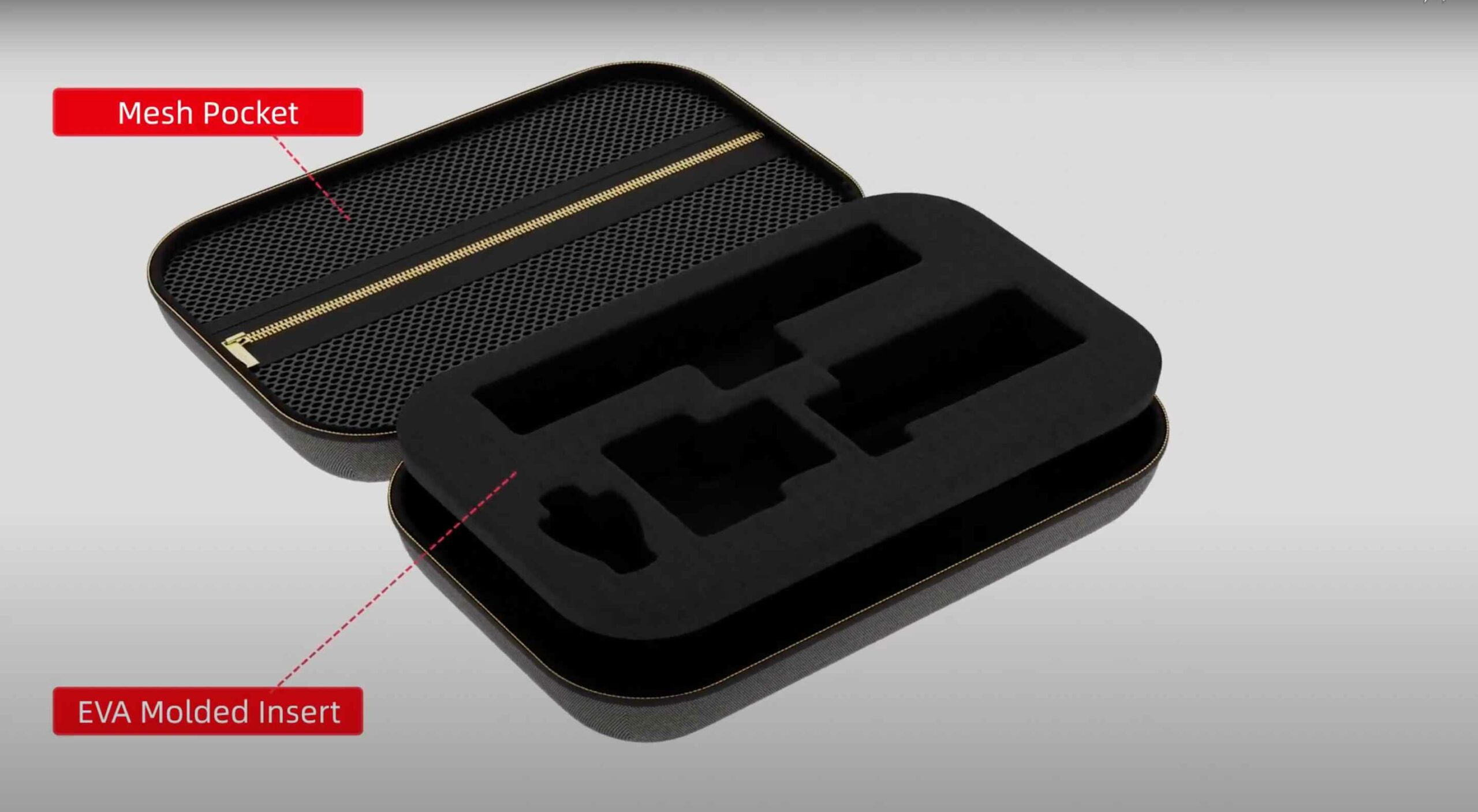

Custom made foam inserts prevent your products from sliding around in an EVA case, and hold everything exactly in its place.

OEM / ODM EVA Cases in-house

As an experienced EVA case manufacturer with a monthly production volume of 200,000 pieces, we provide costs within your budget without sacrificing style & quality.

Manufacturing & 100% Inspection

Our skilled craftsmen will proceed with the manufacturing process, ensuring strict adherence to quality standards at every stage.

Tailored EVA Case to Match Your Unique Demands

Leave a message and one of our experts will reach out to you to discuss your concerns.

EVA Cases Advantages

Upgrade the way you store and sell your goods with EVA cases. Versatile and durable, they provide a secure solution for safeguarding your valuable equipment across a range of industries.

Safety & Protective

Compared to traditional hard cases, EVA cases won't crack easily. The foam inside shows excellent shock-proof performance for delicate items and reduces damage.

Reliable Durability

Abrasion-resistant exteriors ensure both the case and the items inside can travel long and frequently with no damage.

Easy Portability

EVA case's lightweight property makes it a popular choice for many customers. Sleek and ergonomic design enhances its practicality.

Water-resistant & Airtightness

Diverse material options contribute to case capabilities, which prevent damage to the stored items.

Cost-effective Tooling

Compared to other types of boxes and packaging, EVA cases are cost-effective in tooling. You can protect your items well at a pleasant price.

Bespoke Customizability & Brand Image

Cases can be easily tailored to different sizes, shapes, colors, printing properties, etc. to elevate customers' brand image.

Take a Closer Look at How Each of the Processes Work

Raw Material

Before manufacturing, we will source qualified materials from trustworthy factories. These raw materials can include EVA foam sheets, fabrics, zippers, and other hardware items.

Laminating

In this step, our workers will laminate together EVA sheet with exterior material and interior material using eco-friendly adhesive.

Cutting

The laminated material is then cut into the required size and shape using a cutting machine. Precise and accurate cutting makes the pieces assembling process more easily.

Pre-heating

The cut pieces will be pre-heated so that they are pliable and easy to mold.

Thermoforming

Then, with the mold having been carefully designed to the demanded shape and size, an automotive molding machine will create the precise shape.

Trimming

After molding, excess material is trimmed off using a die-cut machine. In that way, the EVA shell looks clean and tidy.

Stitching

Then, our craftsmen will carefully stitch the different pieces together using a sewing machine. This step ensures that the case is strong and durable.

Inspection

All of the products that come out of our hands have gone under 100% inspection. Any defects are identified and corrected at this stage.

Packaging

Once the inspection is complete, you can happily wait for your EVA cases that are carefully packaged.

Tailored EVA Case to Match Your Unique Demands

Leave a message and one of our experts will reach out to you to discuss your concerns.

We Travel, Exhibit, and Partner with Clients

Your Custom EVA Case Project is Just A Click Away!

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Ready To Build Your Custom EVA Case?

Quality & affordable EVA cases from a reliable factory.

- Email: info@kfcase.com

- Phone/WhatsApp: +86 134 1228 8050

- Address: Xinfeng West Road No.279 Building1,Shijie,Dongguan 523290, Guangdong, China