Estuche EVA personalizado

Fábrica de estuches para gafas

En el caso KinFish, Ofrecemos varias opciones personalizadas para crear la carcasa exterior de sus estuches EVA de marca.

- Estuche rígido liviano

- Estuche impermeable

- Cremallera duradera

Estuche de gafas destacado que servimos

Servicio totalmente personalizado

En el caso KinFish, Ofrecemos una amplia gama de formas de poner su logotipo en la carcasa del estuche., cremallera, o etiqueta, dependiendo del diseño de su logotipo, tu identidad de marca, y tu presupuesto.

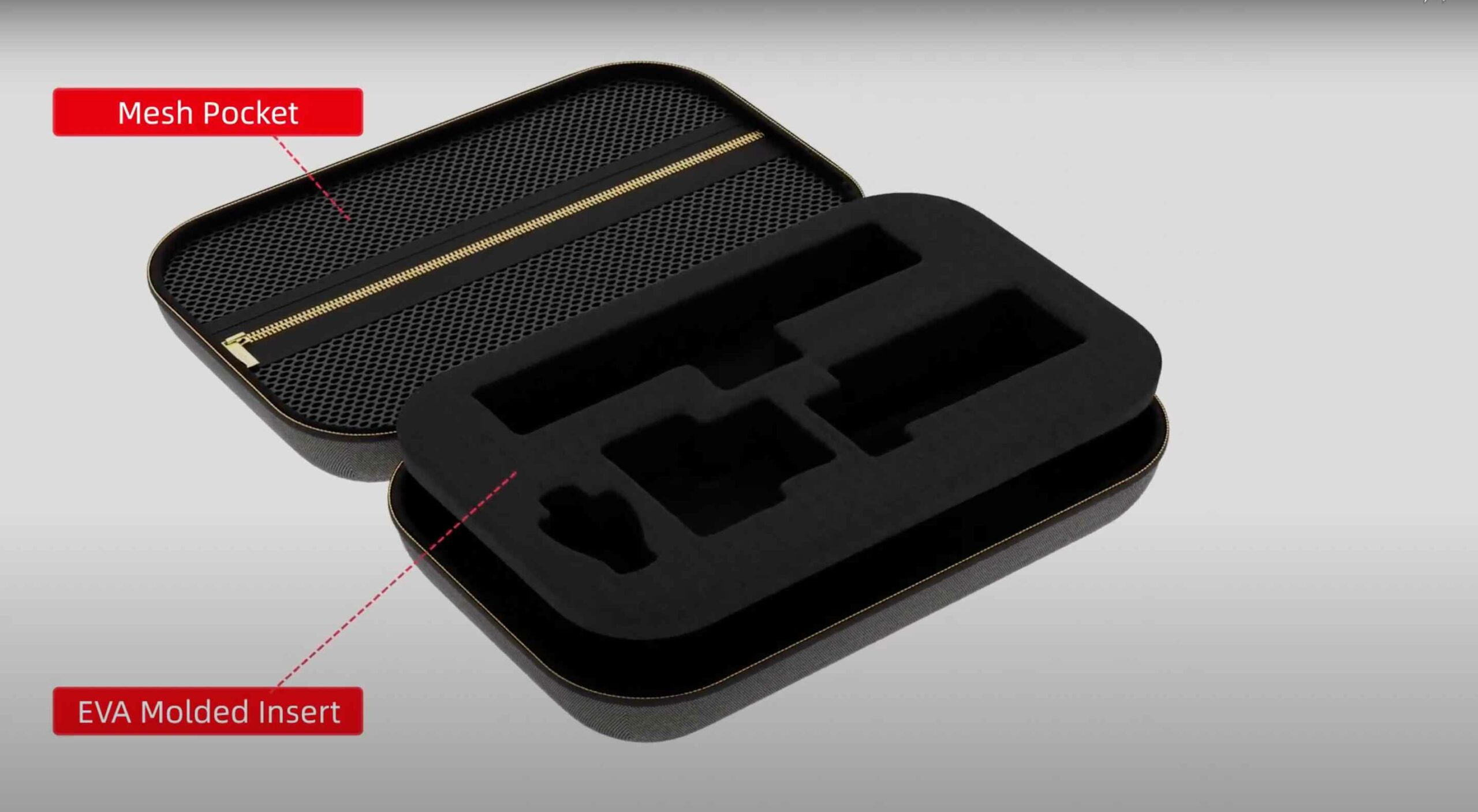

Característica del estuche rígido de Eva

Este estuche rígido de viaje de EVA es elegante y seguro, Proporciona protección resistente al agua contra impactos y choques sin dejar de ser elegante y amigable para los negocios..

Estuche EVA para deportes & Al aire libre

Ya sea que sea un fabricante que busque estuches de EVA para empaquetar y proteger sus productos o que busque estuches al por mayor para su negocio., Ofrecemos soluciones completas personalizadas para usted..

Estuche de EVA personalizado para satisfacer sus demandas únicas

Comuníquese con nosotros para casos de transporte de EVA personalizados que proporcionen protección y almacenamiento incomparables.

Solicitar una cotización

Hable con nosotros sobre sus ideas aproximadas y necesidades personalizadas., nuestros expertos en casos se comunicarán con usted dentro de 24 horas.

Calidad & estuches EVA asequibles

De una fábrica confiable.

Nuestra fabricación interna & 100% inspección asegúrese de recibir casos de EVA personalizados con calidad consistente y premium, y a precios asequibles.

Soporte de diseño en profundidad

100% Personalizado totalmente personalizable, Diseños elegantes & Logo, Color personalizado / Forma / Tamaño / Material

Más fácil de moldear & Baja tasa de rechazo

Con bajo costo de herramientas, una espuma EVA se puede moldear a cualquier forma, cualquier tamaño que quieras.

MOQ bajo para pedidos pequeños

En 7 días, Obtendrá un prototipo del estuche de EVA y lo probará para comprobar su ajuste., funcionalidad, y durabilidad.

Acerca del caso KinFish

Diseñar casos de EVA

Haga clic en vídeo aquí

KinFish Case es un fabricante de estuches de EVA personalizados en China. Para KinFish, construir una caja de EVA es paralelo a construir una casa, ya que ambos requieren consideración diseño estructural, utilización eficiente del espacio, materiales confiables, y técnicas precisas.

KinFish Case está especializado en estuches de EVA para una amplia gama de mercados., incluido electrónica de consumo, suministro medico, exterior, audio y más. Fundas de neopreno, estuches de plástico con cremallera, También se ofrecen mochilas y bolsos con cordón.. Todos los productos se fabrican según ISO. 9001 estándar y se puede pasar Alcance, RoHS, SGS y otras pruebas ambientales.

Bienvenido a productos personalizados!

Troquelado

con más 10 años de proceso de moldeo, Podemos hacer que su caso tenga cualquier forma según sea necesario..

Puntadas

Nuestros artesanos coserán cuidadosamente las diferentes piezas utilizando una máquina de coser.. Este paso garantiza que el estuche sea resistente y duradero..

Personalización

Los insertos de espuma hechos a medida evitan que sus productos se deslicen en una caja de EVA, y mantener todo exactamente en su lugar.

OEM / Casos ODM EVA internos

Como fabricante experimentado de cajas de EVA con un volumen de producción mensual de 200,000 piezas, Ofrecemos costos dentro de su presupuesto sin sacrificar el estilo. & calidad.

Fabricación & 100% Inspección

Nuestros expertos artesanos procederán con el proceso de fabricación., Garantizar el estricto cumplimiento de los estándares de calidad en cada etapa..

Estuche de EVA personalizado para satisfacer sus demandas únicas

Deje un mensaje y uno de nuestros expertos se comunicará con usted para discutir sus inquietudes..

Ventajas de los casos EVA

Mejora la forma de almacenar y vender tus productos con estuches de EVA. Versátil y duradero, Proporcionan una solución segura para proteger su valioso equipo en una variedad de industrias..

Seguridad & Protector

En comparación con los estuches rígidos tradicionales, Las fundas de EVA no se agrietan fácilmente. El interior de espuma muestra un excelente rendimiento a prueba de golpes para artículos delicados y reduce los daños..

Durabilidad confiable

Los exteriores resistentes a la abrasión garantizan que tanto el estuche como los elementos del interior puedan viajar durante mucho tiempo y con frecuencia sin sufrir daños..

Fácil portabilidad

La propiedad liviana del estuche EVA lo convierte en una opción popular para muchos clientes. El diseño elegante y ergonómico mejora su practicidad..

Resistente al agua & Hermeticidad

Diversas opciones de materiales contribuyen a las capacidades del estuche., que evitan daños a los artículos almacenados.

Herramientas rentables

Comparado con otros tipos de cajas y embalajes., Los casos de EVA son rentables en herramientas. Puedes proteger bien tus artículos a un precio agradable..

Personalización a medida & Imagen de marca

Los estuches se pueden adaptar fácilmente a diferentes tamaños, formas, bandera, propiedades de impresión, etc.. para elevar la imagen de marca de los clientes.

Observe más de cerca cómo funciona cada uno de los procesos

Materia prima

Antes de fabricar, Obtendremos materiales calificados de fábricas confiables.. Estas materias primas pueden incluir láminas de espuma EVA., telas, cremalleras, y otros artículos de hardware.

Laminado

en este paso, Nuestros trabajadores laminarán láminas de EVA con material exterior y material interior utilizando adhesivo ecológico..

Corte

Luego, el material laminado se corta en el tamaño y la forma requeridos utilizando una máquina cortadora.. El corte preciso y preciso facilita el proceso de ensamblaje de las piezas..

Precalentamiento

Las piezas cortadas se precalentarán para que sean flexibles y fáciles de moldear..

Termoformado

Entonces, con el molde cuidadosamente diseñado según la forma y el tamaño exigidos, una máquina de moldeo automotriz creará la forma precisa.

Guarnición

Después del moldeado, El exceso de material se recorta con una máquina troqueladora.. De esa manera, la carcasa de EVA se ve limpia y ordenada.

Puntadas

Entonces, Nuestros artesanos coserán cuidadosamente las diferentes piezas utilizando una máquina de coser.. Este paso garantiza que el estuche sea resistente y duradero..

Inspección

Todos los productos que salen de nuestras manos se han hundido. 100% inspección. Cualquier defecto se identifica y corrige en esta etapa..

Embalaje

Una vez completada la inspección, Puede esperar felizmente sus estuches de EVA que están cuidadosamente empaquetados..

Estuche de EVA personalizado para satisfacer sus demandas únicas

Deje un mensaje y uno de nuestros expertos se comunicará con usted para discutir sus inquietudes..

Viajamos, Anexo, y socio con clientes

Su proyecto de caso de EVA personalizado es A sólo un clic de distancia!

Si estás interesado en nuestros productos y quieres conocer más detalles,por favor deja un mensaje aquí,le responderemos tan pronto como podamos.

Listo para construir su estuche EVA personalizado?

Calidad & Estuches EVA asequibles de una fábrica confiable.

- Correo electrónico: info@kfcase.com

- Teléfono/WhatsApp: +86 134 1228 8050

- DIRECCIÓN: Xinfeng West Road No.279 Edificio 1, Shijie,Dongguan 523290, Cantón, Porcelana