Kasing EVA sangat penting untuk melindungi berbagai produk, dari elektronik ke alat. Menemukan produsen kasus EVA yang tepat sangat penting untuk memastikan kualitas dan daya tahan produk akhir.

Memilih produsen yang andal dapat menghemat waktu, dan uang, dan pastikan kasus Anda memenuhi kebutuhan spesifik Anda, apakah untuk produksi massal atau Desain khusus.

Dalam artikel ini, Kami akan mengeksplorasi daftar pemasok dan produsen kandang EVA berkualitas tinggi di Cina. Daftar ini tidak ada dalam urutan tertentu dan Anda dapat memilih sesuai dengan kebutuhan Anda!

Bagaimana kasus EVA dibuat?

Kami menyebutkan di blog sebelumnya bagaimana Soft Shell EVA diproses dan diproduksi di pabrik.

Pemilihan materi

Proses dimulai dengan memilih busa EVA berkualitas tinggi. Produsen kasus EVA dengan hati -hati memilih nilai materi EVA yang tepat berdasarkan aplikasi (MISALNYA., Perlindungan Dampak, fleksibilitas, dan bantalan).

Memotong dan membentuk

Busa Eva dipotong menjadi seprai dan dibentuk menjadi bentuk yang diinginkan. Beberapa produsen menggunakan teknik laser atau cutting untuk mencapai dimensi yang tepat.

Langkah ini memastikan bahwa kasus tersebut sesuai dengan produk yang dimaksud, seperti perangkat seluler, kamera, atau item halus lainnya.

Cetakan atau kompresi

Busa kemudian ditempatkan dalam cetakan dan mengalami kompresi, yang membentuknya menjadi cangkang yang kokoh dan pelindung.

Untuk kasus yang lebih kaku, Busa dipanaskan dan ditekan untuk membuat struktur padat, menawarkan lebih banyak dampak resistensi.

Panas menekan (Untuk kasing keras)

Jika kasing EVA dirancang untuk menjadi cangkang keras, Pers panas digunakan untuk mengikat busa ke lapisan eksternal, memberikan kekakuan dan daya tahan.

Ini memastikan kasing dapat menahan tekanan eksternal sambil mempertahankan bentuknya.

Menambahkan fitur

Fitur tambahan seperti ritsleting, menangani, tali, atau bantalan busa interior ditambahkan selama tahap ini.

Banyak produsen kasus EVA juga menawarkan opsi kustomisasi seperti embossing logo atau perubahan warna untuk memenuhi spesifikasi klien.

Kontrol kualitas dan inspeksi akhir

Produk akhir diperiksa untuk cacat, memastikan bahwa setiap kasus memenuhi standar kualitas tertinggi sebelum pengiriman. Di samping itu, itu memiliki banyak yang lain manfaat.

Setelah lulus inspeksi, Kasing dikemas dan disiapkan untuk pengiriman ke pelanggan.

Mengapa Memilih Produsen Kasus Eva Teratas?

Bekerja dengan papan atas Produsen kasus EVA Membawa sejumlah keunggulan signifikan yang dapat sangat meningkatkan kualitas produk dan efisiensi bisnis secara keseluruhan. Berikut adalah beberapa manfaat utama:

Kontrol kualitas yang unggul

Produsen terkemuka memastikan bahwa setiap kasus EVA diuji secara menyeluruh untuk kualitas, memastikan kinerja yang konsisten. Ini termasuk:

- Pengujian yang ketat

Setiap kasus EVA menjalani pengujian menyeluruh untuk daya tahan, kekuatan, dan fungsionalitas untuk memastikannya memenuhi standar industri.

- Kinerja yang konsisten

Produsen dengan komitmen terhadap jaminan kualitas bahwa setiap kasus melakukan secara konsisten dari waktu ke waktu, Mengurangi kemungkinan cacat atau masalah kinerja.

- Inspeksi Bahan

Produsen tepercaya memastikan bahwa bahan baku bersumber dengan hati -hati dan diuji sebelum diproduksi untuk menghindari masalah kualitas potensial.

Desain yang dapat disesuaikan

Produsen teratas menawarkan opsi desain yang fleksibel, memungkinkan Anda untuk membuat kasus unik yang selaras dengan kebutuhan branding atau produk Anda. Ini termasuk:

- Pilihan desain yang disesuaikan

Anda dapat memilih dari berbagai bentuk, ukuran, warna, dan fitur untuk membuat kasus EVA yang selaras dengan produk atau branding Anda.

- Peluang branding

Produsen terkemuka memungkinkan Anda untuk menambahkan logo khusus, teks, dan elemen branding lainnya untuk membuat produk Anda menonjol.

- Fitur Khusus

Apakah itu kompartemen tambahan, menangani, atau penutupan unik, Produsen teratas dapat menggabungkan fitur yang meningkatkan fungsionalitas dan daya tarik kasing.

Harga kompetitif

Produsen terkemuka memiliki infrastruktur dan pengalaman untuk menawarkan harga yang lebih baik tanpa mengurangi kualitas.

- Infrastruktur yang mapan

Produsen terkemuka mendapat manfaat dari fasilitas produksi canggih dan skala ekonomi, yang memungkinkan mereka untuk menawarkan harga yang lebih kompetitif.

- Proses produksi yang dioptimalkan

Dengan pengalaman bertahun -tahun, Produsen ini merampingkan operasinya untuk mengurangi biaya, meneruskan tabungan itu kepada pelanggan mereka.

Keandalan dan ketepatan waktu

- Pengiriman tepat waktu

Produsen berpengalaman terampil dalam mengelola jadwal produksi, memastikan bahwa pesanan dikirimkan segera tanpa penundaan yang tidak perlu.

- Komunikasi yang jelas

Produsen yang andal memberi Anda informasi tentang status pesanan Anda, memastikan bahwa harapan dikelola dan setiap penundaan potensial dikomunikasikan sebelumnya.

Tips untuk menemukan produsen kasus EVA terbaik di China

Saat mencari produsen kasus EVA yang andal di Cina, Sangat penting untuk mengikuti pendekatan terstruktur untuk memastikan bahwa Anda memilih mitra terbaik untuk kebutuhan bisnis Anda. Di bawah ini adalah faktor utama yang perlu dipertimbangkan dalam proses pengambilan keputusan Anda:

Meneliti dan mengevaluasi produsen

Penelitian produsen kasus EVA terkemuka di platform seperti Alibaba, Made-in-China, dan sumber global, Berfokus pada mereka yang memiliki peringkat yang kuat, Ulasan, dan pengalaman industri.

Persempit daftar Anda dengan mempertimbangkan produsen yang berspesialisasi dalam jenis kasus EVA yang Anda butuhkan, karena mereka menawarkan produk berkualitas lebih tinggi. Pastikan jajaran produk mereka selaras dengan spesifikasi dan kebutuhan kustomisasi Anda untuk hasil terbaik.

Nilai standar kontrol kualitas

Kontrol kualitas sangat penting saat memilih produsen kasus EVA. Produsen yang andal akan menerapkan sistem kontrol kualitas yang ketat, termasuk:

- Inspeksi Bahan Baku

Memastikan penggunaan busa EVA berkualitas tinggi.

- Pemeriksaan dalam proses

Memantau produksi untuk mempertahankan standar produk yang konsisten.

- Pengujian Produk Akhir

Memverifikasi daya tahan dan fungsionalitas.

Mengevaluasi komunikasi dan dukungan pelanggan

Komunikasi yang efektif adalah kunci kemitraan yang sukses. Pilih produsen yang responsif, mahir dalam bahasa Inggris (atau bahasa pilihan Anda), dan terbuka untuk kolaborasi. Dukungan pelanggan yang kuat sama pentingnya untuk mengatasi masalah pasca-produksi, seperti cacat atau penundaan pengiriman. Cari produsen yang menyediakan pembaruan rutin dan dukungan berkelanjutan di seluruh produksi.

Pertimbangkan persyaratan harga dan pembayaran

Sedangkan harga adalah faktor penting, Seharusnya tidak mengkompromikan kualitas. Produsen top mencapai keseimbangan sempurna antara harga kompetitif dan kualitas produk yang sangat baik. Saat menilai biaya, mempertimbangkan:

- Struktur harga

Bandingkan kutipan dari beberapa produsen untuk menemukan nilai terbaik.

- Diskon volume

Tanyakan tentang diskon untuk pesanan curah, karena banyak produsen menawarkan harga yang lebih baik untuk jumlah yang lebih besar.

- Hal dpt diperundingkan

Diskusikan ketentuan pembayaran yang fleksibel, jadwal pengiriman, dan diskon potensial untuk kontrak jangka panjang atau pesanan yang lebih besar untuk mendapatkan penawaran terbaik.

Mengevaluasi kemampuan kustomisasi

Kustomisasi adalah faktor kunci saat memilih kasus EVA, Apalagi untuk tujuan branding. Verifikasi jika produsen menawarkan:

- Fleksibilitas desain

Pastikan mereka dapat mengakomodasi pilihan warna, membentuk, ukuran, logo, dan fitur tambahan seperti kompartemen atau pegangan.

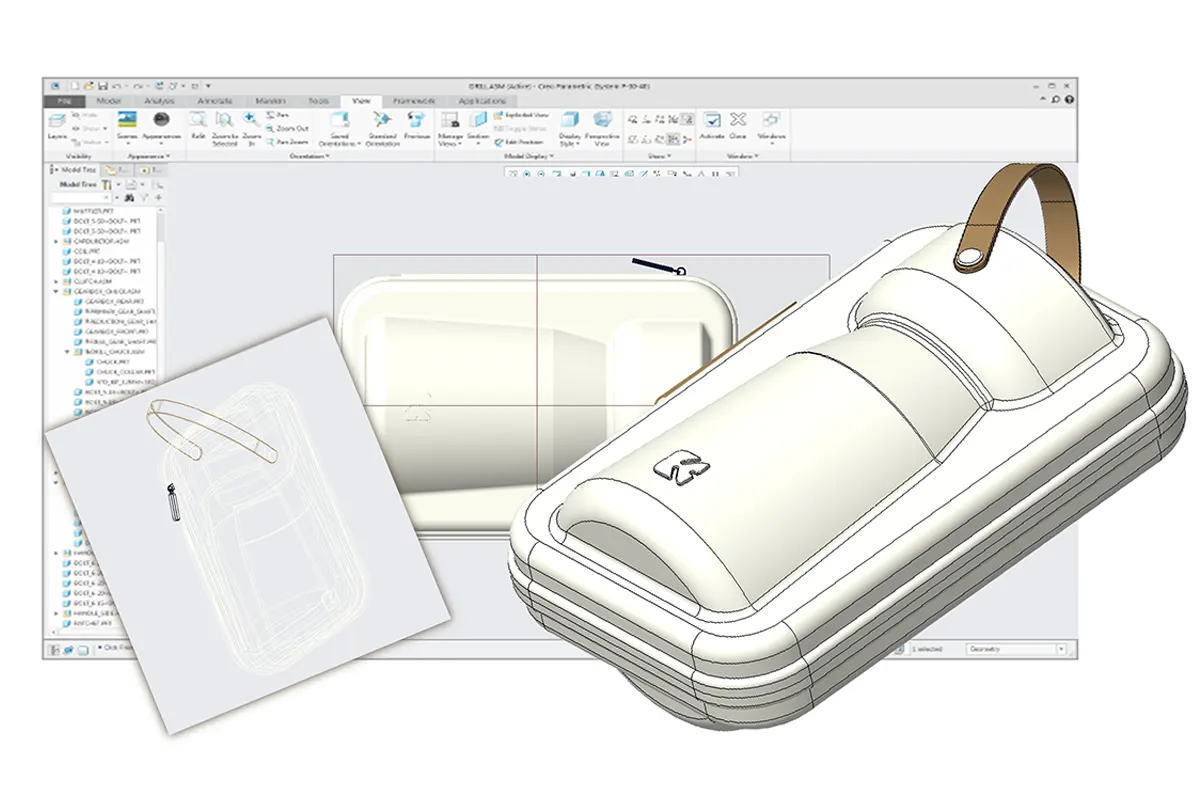

- Prototyping dan sampel

Produsen harus dapat menghasilkan prototipe atau sampel untuk persetujuan Anda sebelum produksi massal. Ini memberi Anda kesempatan untuk mengevaluasi desain dan membuat penyesuaian sesuai kebutuhan.

Memahami proses pengiriman dan impor

Produsen harus memiliki pengetahuan tentang proses pengiriman dan impor. Pertimbangan utama termasuk:

- Opsi Pengiriman

Pabrikan harus menawarkan metode pengiriman yang andal dan efisien ke wilayah Anda, dengan kapasitas untuk menangani pengiriman curah.

- Dukungan Bea Cukai dan Impor

Pastikan pabrikan membantu dengan dokumentasi bea cukai, bea impor, dan pajak.

- Kemasan

Tanyakan tentang opsi pengemasan mereka untuk memastikan bahwa kasus EVA dikemas dengan aman dan dilindungi selama transit.

Terlepas dari jenis barang apa yang Anda impor dari China, Anda biasanya perlu mengevaluasi poin -poin di atas untuk mengonfirmasi apakah itu pabrikan yang Anda butuhkan. Tentu saja, berbagai jenis produk memiliki perbedaan halus.

Pilih Kinfish Case = Pilih Sukses

Sebagai inovatif & Pabrik Kasus Kustom Kustom khusus, Kinfishcase telah sangat memperhatikan masalah kualitas dan inspeksi teknis keselamatan.

Kami menawarkan produk khusus yang disesuaikan dengan kebutuhan Anda, dan kami proses kolaborasi dirancang untuk memastikan kepuasan Anda. Apakah Anda sudah memiliki visi yang jelas atau membutuhkan bimbingan ahli, Kami di sini untuk membantu Anda setiap langkah.

Dalam hal jenis produk, Kami tidak hanya meliput medis, elektronik, Olahraga luar ruangan, dan audio profesional tetapi juga memiliki kit alat yang menyertainya untuk Anda pilih untuk memastikan bahwa produk Anda dapat ditampilkan di lemari layar kapan saja dan di mana saja.

Kesimpulan

Memilih produsen kasus EVA terbaik sangat penting untuk bisnis yang mencari berkualitas tinggi, dapat diandalkan, dan kasus yang hemat biaya.

Luangkan waktu untuk meneliti produsen potensial, mengevaluasi penawaran mereka, dan memastikan mereka memenuhi standar kualitas dan layanan Anda. Investasi ini akan membuahkan hasil dalam bentuk produk yang lebih baik dan hubungan bisnis jangka panjang.

Mengimpor Produk dari Cina bisa menjadi usaha bisnis yang menguntungkan, asalkan itu dilakukan secara strategis. Ini berarti melakukan penelitian menyeluruh, memilih produk yang tepat, dan bermitra dengan pemasok yang tepat.