Hüter der Wertsachen, Architekten des Stils

Innovativ & Dedizierte benutzerdefinierte EVA -Fallfabrik

Über den KinFish-Fall

Wir entwickeln seit jeher maßgeschneiderte Lösungen 2012

“Denken Sie über den Tellerrand hinaus.” – Das Ethos fasst unsere DNA präzise zusammen. Unsere Mission ist klar: um maßgeschneiderte Kofferlösungen zu schaffen, die so einzigartig sind wie jeder unserer Kunden, Das Unternehmen deckt ein breites Spektrum an Märkten ab, von der Medizin bis hin zu Outdoor- und Unterhaltungselektronik. Das sind wir – Dongguan KinFish Technology Co., Ltd. (KinFish-Fall), Eine kreative Tragetaschenlösung & produzierendes Unternehmen.

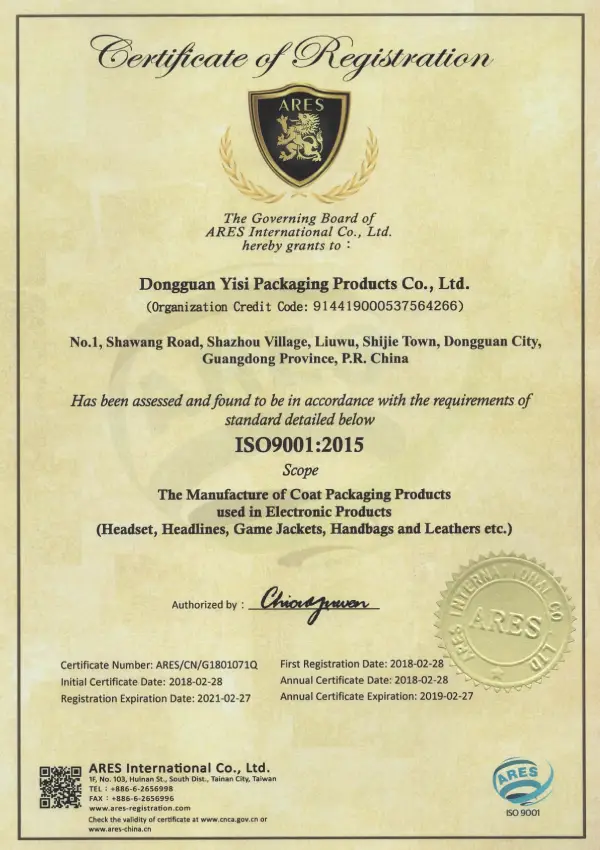

Befindet sich in Dongguan, China mit über 5,000 Quadratmeter Anlage, Qualität steht für uns immer an erster Stelle, Deshalb verwalten wir unsere Prozesse nach ISO 9001 Validierung und Einhaltung der Proposition 65, RoHS, und REACH-Vorschriften für unsere Materialien. Darüber hinaus, Unsere monatliche Ausbeute an kundenspezifischen Hüllen hat erreicht 200,000 Stücke.

Aber das ist es, was uns wirklich auszeichnet – Wir sind auf lange Sicht dabei. Bauen nachhaltig, Vertrauenswürdige Beziehungen zu unseren Kunden sind unsere Grundüberzeugung. Also, ob Sie auf der Suche nach einem eleganten Look sind, robust, oder irgendwo dazwischen ein maßgeschneidertes EVA-Gehäuse, KinFish Case ist Ihr Partner. Lassen Sie uns gemeinsam auf diese aufregende Reise gehen!

Mission

Machen Sie Kommunikation & Anpassung einfacher.

Vision

Sicherung & Marken mit Leidenschaft für Exzellenz stärken.

Wert

Ein Kofferbauer, der gerne kreiert und gestaltet.

Maßgeschneidert ist alles, was wir tun - Unsere Philosophie

Design, und Innovationen voranzutreiben sind unsere Leidenschaft

Kommen Sie dem KinFish-Fall näher, wo Design nicht nur ein Job ist, Es ist unsere wahre Leidenschaft! Wir sind der festen Überzeugung, dass ein außergewöhnliches EVA-Gehäuse nicht nur eine atemberaubende Ästhetik, sondern auch etwas Einzigartiges besitzen sollte “Seele” das bringt praktischen Nutzen, genau wie wir Menschen.

Wenn Sie mit uns zusammenarbeiten, Sie werden unser außergewöhnliches Team aus erfahrenen und kompetenten Experten treffen, die Meister der effizienten Kommunikation und effektiven Problemlösung sind. Hier kommt nun der wirklich interessante Teil: obwohl wir in Ostasien ansässig sind, Wir arbeiten nach einem westlichen Zeitplan.

Ja, Du hast es richtig gehört! Sie genießen das gleiche Maß an Professionalität und Komfort wie bei jedem anderen westlichen Unternehmen. Wir sind die Brücke zwischen den Kulturen, Wir bieten Ihnen das Beste aus beiden Welten.

Seien Sie also beruhigt und bereiten Sie sich auf ein aufregendes Abenteuer voller Kreativität vor, Innovation, und jede Menge Spaß!

Unser Engagement für Nachhaltigkeit

Wir sind Öko-Krieger

Bei KinFish Case, Es geht uns nicht nur darum, außergewöhnliche EVA-Hüllen herzustellen – wir haben die Mission, den Planeten zu retten, einen Fall nach dem anderen.

Wir haben einige wirklich coole Tricks auf Lager, wenn es um die Verantwortung für die Umwelt geht. Unsere Fabrik ist mit High-Tech-Reinigern ausgestattet, die den Wasserverbrauch und die lästigen Industrieabgase minimieren. Aber warte, da ist noch mehr! Wir verfügen über ein engagiertes Team von Abfallkämpfern, die sich engagieren, um alle Materialien zu sammeln und wiederzuverwenden, denen ein zweites Leben gegeben werden kann. Recycling ist unser zweiter Vorname!

Wir sind stolz darauf, sagen zu können, dass wir einer der wenigen Hersteller von EVA-Koffer in China sind, die eine Umweltverträglichkeitsprüfung erhalten haben. Es ist nicht nur ein Zertifikat an der Wand – es ist ein Symbol für unser unerschütterliches Engagement für Nachhaltigkeit. Wir legen die Messlatte ständig höher, Wir finden neue Wege, um Mutter Erde zu schützen und eine positive Wirkung zu erzielen.

Verschaffen Sie sich einen schnellen Überblick über unseren Prozess

In unserer Fabrik für maßgeschneiderte EVA-Koffer, Bei der Herstellung Ihrer Artikel wenden wir ein strenges und aufwändiges neunstufiges Produktionsverfahren an. Von der sorgfältigen Materialauswahl bis zur gründlichen Prüfung der Verpackung, Jede Phase wird von bestimmten Mitarbeitern gut betreut. Unser Engagement für Exzellenz zeigt sich in jedem Produkt, das wir herstellen.

Schauen Sie sich genauer an, wie die einzelnen Prozesse funktionieren

Rohstoff

Vor der Herstellung, Wir beziehen qualifizierte Materialien von vertrauenswürdigen Fabriken. Zu diesen Rohstoffen können EVA-Schaumplatten gehören, Stoffe, Reißverschlüsse, und andere Hardware-Artikel.

Laminieren

In diesem Schritt, Unsere Mitarbeiter laminieren die EVA-Folie mit Außenmaterial und Innenmaterial unter Verwendung von umweltfreundlichem Klebstoff.

Schneiden

Anschließend wird das laminierte Material mit einer Schneidemaschine in die gewünschte Größe und Form geschnitten. Präzises und genaues Schneiden erleichtert den Zusammenbau der Teile.

Vorheizen

Die geschnittenen Stücke werden vorgewärmt, damit sie biegsam und leicht formbar sind.

Thermoformen

Dann, Die Form wurde sorgfältig auf die gewünschte Form und Größe abgestimmt, Eine Automobilformmaschine erzeugt die präzise Form.

Trimmen

Nach dem Formen, Überschüssiges Material wird mit einer Stanzmaschine abgeschnitten. Auf diese Weise, Die EVA-Schale sieht sauber und aufgeräumt aus.

Nähen

Dann, Unsere Handwerker nähen die verschiedenen Teile sorgfältig mit einer Nähmaschine zusammen. Dieser Schritt stellt sicher, dass das Gehäuse robust und langlebig ist.

Inspektion

Alle Produkte, die aus unseren Händen kommen, sind untergegangen 100% Inspektion. Eventuelle Mängel werden in dieser Phase identifiziert und behoben.

Verpackung

Sobald die Inspektion abgeschlossen ist, Sie können sorglos auf Ihre sorgfältig verpackten EVA-Koffer warten.

Wir reisen, Ausstellen, und Partner mit Kunden

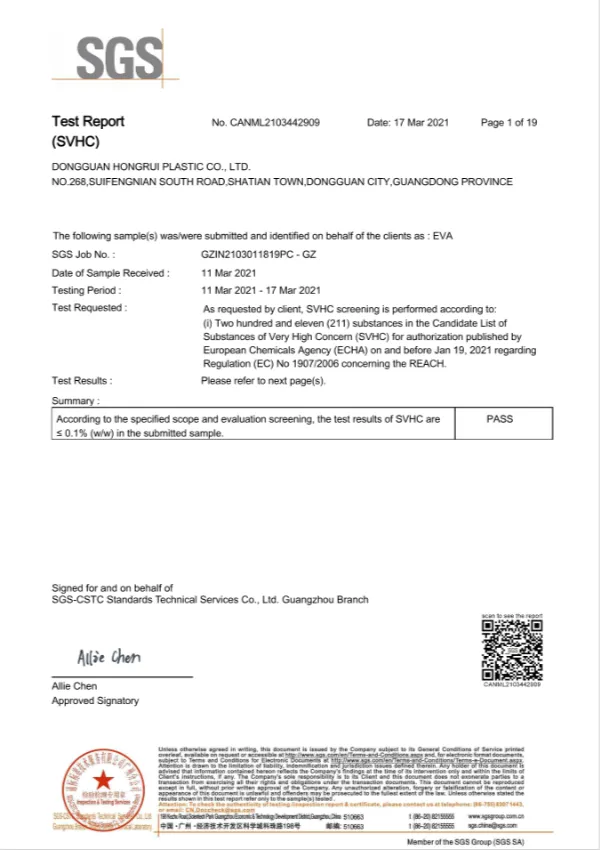

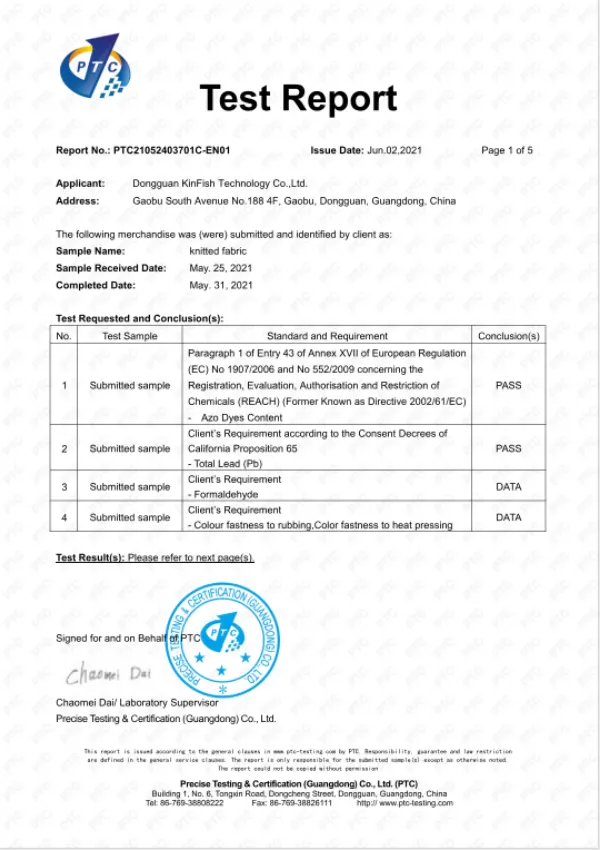

Zertifizierungen von KINFISH

Unser Hauptziel ist es, unseren Kunden als professioneller EVA-Kofferlieferant den besten Service und höchste Qualität zu bieten. Dies erreichen wir durch die genaue Beachtung jedes einzelnen Schritts unseres Produktionsprozesses, Dazu gehört eine strenge Qualitätskontrolle nach internationalen Standards.