Benutzerdefinierter kooperativer EVA-Fallprozess

Übersicht über benutzerdefinierte Prozesse

Bei KinFish Case, Wir wissen, dass es von entscheidender Bedeutung ist, den richtigen Koffer für Ihre Ausrüstung zu haben. Aus diesem Grund bieten wir maßgeschneiderte EVA-Koffer an, die genau auf Ihre Bedürfnisse zugeschnitten sind.

Unser Prozess garantiert Ihre Zufriedenheit, Egal, ob Sie bereits Ideen haben oder unsere fachkundige Unterstützung benötigen. Mit Fokus auf Präzision und Liebe zum Detail, Wir arbeiten mit Ihnen von der Entdeckung und Beratung bis zur endgültigen Lieferung Ihrer maßgeschneiderten EVA-Koffer zusammen.

SCHRITT 1

Beratung & Entdeckung

Hallo! Wir erwarten Sie. Lasst uns ein wenig voneinander lernen.

Um Ihre individuellen Anforderungen an den EVA-Koffer besser zu verstehen, Wir können jederzeit einen Videoanruf vereinbaren.

Dies ermöglicht uns eine individuellere und effizientere Beratung – Wir können den Zweck des Falles besprechen, Größe, Form, Materialien, und andere notwendige Details wie persönliches Gespräch. Dadurch, Wir können ein Produkt entwerfen und herstellen, das Ihren spezifischen Anforderungen entspricht und Ihre Erwartungen übertrifft.

Wenn Sie bereits eine Designdatei haben:

Wenn Sie keine Designdatei haben:

SCHRITT 2

Bereiten Sie sich auf das Design vor

Festhalten, Beeilen Sie sich noch nicht. Wir kennen uns einfach.

Bevor wir mit dem Entwerfen beginnen, Möglicherweise müssen wir eine Geheimhaltungsvereinbarung unterzeichnen(NDA) um alle unsere vertraulichen Informationen zu schützen.

Basierend auf den während der Entdeckungsphase gesammelten Informationen erstellen wir einfache Zeichnungen und 2D-Darstellungen des Falles. Dies hilft Ihnen, das Produkt zu visualisieren und alle notwendigen Änderungen vorzunehmen, bevor wir mit dem 3D-Modell fortfahren.

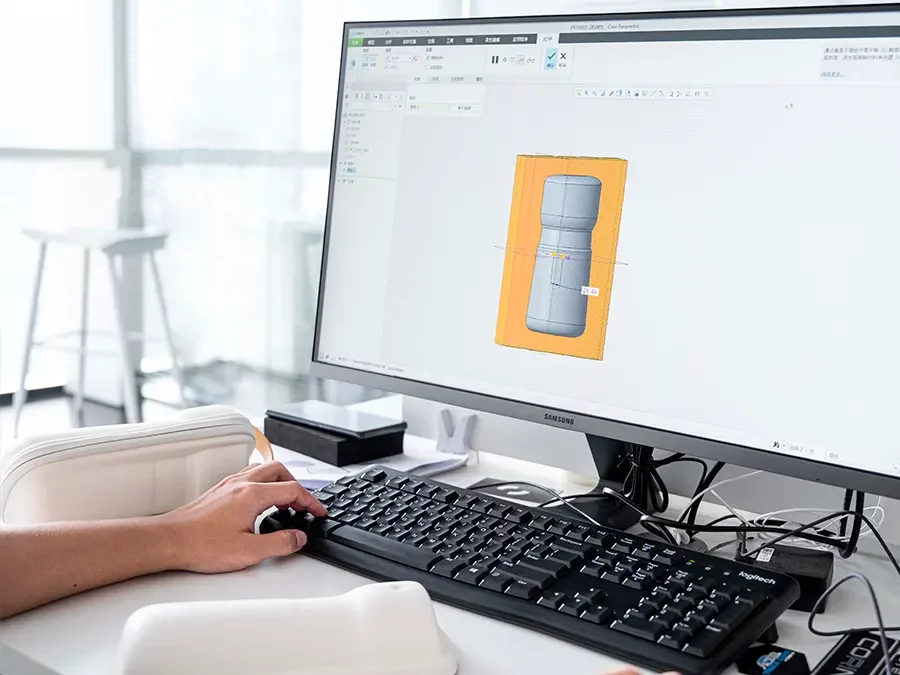

SCHRITT 3

Präsentation

Jetzt denke ich, dass es die Phase ist, in der wir uns beide über etwas einig sind.

Unser Team erstellt ein detailliertes 3D-Modell des EVA-Gehäuses. Durch Überprüfung des 3D-Modells, Sie können letzte Änderungen vornehmen, bevor wir mit der Werkzeugphase fortfahren

Wir bieten kostenlose Designdienstleistungen an und sind bestrebt, den ersten Entwurf innerhalb dieses Bereichs bereitzustellen 2 Tage.

SCHRITT 4

Werkzeuge

Jetzt machen wir es möglich.

Wir stellen die Werkzeuge her, die zum Formen des EVA-Gehäuses erforderlich sind. Unser Team stellt sicher, dass die Werkzeuge unseren hohen Ansprüchen an Präzision und Haltbarkeit entsprechen. In 5 Zu 7 Tage, Du wirst es treffen.

SCHRITT 5

Prototyp

Bereit, unsere Kunstwerke kennenzulernen?

Wir beginnen mit der Herstellung Ihres individuellen Formgehäuses und der Musterproduktion. Dadurch können wir einen Prototyp des EVA-Koffers erstellen und ihn auf Passform testen, Funktionalität, und Haltbarkeit. Bei Bedarf, Wir nehmen eventuelle Anpassungen vor, bevor wir mit der Massenproduktion beginnen.

SCHRITT 6

Massenproduktion

Woah! Es gibt so viele davon.

Sobald der Prototyp genehmigt ist, Wir gehen zum Herstellungsprozess über. Unsere erfahrenen Mitarbeiter fertigen Ihre EVA-Koffer sorgfältig mit verschiedenen Techniken an, inklusive Laminieren, Schneiden, Thermoformen, Nähen, Trimmen, usw. Hochwertige Materialien und modernste Maschinen sorgen für Präzision und Langlebigkeit.

Von Anfang bis Ende, Wir überwachen jeden Schritt des Herstellungsprozesses genau, um die Qualität Ihrer Produkte sicherzustellen.

SCHRITT 7

100% Gründliche Inspektion

Achtung bitte, Keiner von ihnen kann entkommen.

Ein strenger Inspektions- und Testprozess, vom Aussehen bis hin zu den kleinsten Accessoires im Innen- oder Außenbereich, wird durchgeführt, um sicherzustellen, dass jeder maßgeschneiderte EVA-Koffer unseren Standards für Qualität und Funktionalität entspricht. Von 100% Inspektion, wir meinen es wirklich ernst.

SCHRITT 8

Lieferung

Voila! Du hast sie.

Für die Massenproduktion, Es dauert etwa einen Monat, bis Sie Ihre maßgeschneiderten EVA-Hüllen erhalten. Wir verstehen, dass eine pünktliche Lieferung von entscheidender Bedeutung ist, Wir sorgen dafür, dass Sie Ihre Koffer pünktlich und in gutem Zustand erhalten. Wir sind bestrebt, während des gesamten Prozesses exzellenten Kundenservice und Support zu bieten.