Quand il s'agit de choisir le bon type de mousse pour vos projets, La mousse Eva et la mousse PE sont deux options populaires qui sont souvent en considération. Ces deux matériaux ont des caractéristiques distinctes qui les distinguent les uns des autres, les rendre adaptés à différentes applications. Dans cet article, Nous nous plongerons dans les différences entre EVA MoUam et PE Mousse pour vous aider à prendre une décision éclairée pour vos besoins spécifiques.

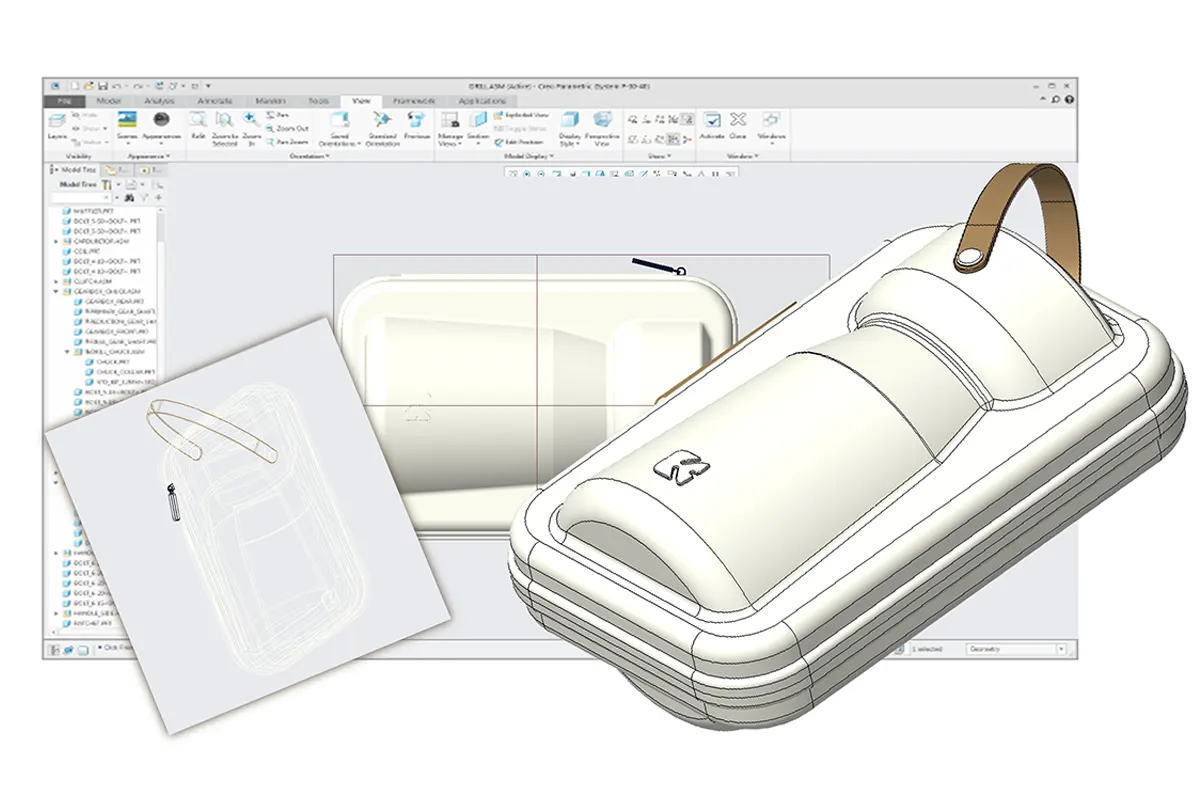

Qu'est-ce que la mousse Eva?

Mousse EVA, abréviation de mousse en acétate de vinyle d'éthylène, est un matériau polyvalent connu pour sa résilience et sa durabilité. Il s'agit d'une mousse à cellule fermée qui offre des propriétés d'amorti et d'absorption des chocs, Le rendre idéal pour un large éventail d'applications. La mousse EVA est couramment utilisée dans des industries telles que les équipements sportifs, conditionnement, et artisanat en raison de sa nature légère et de sa facilité de personnalisation.

De quoi est fait en mousse eva?

La mousse Eva est composée de Copolymères d'éthylène et d'acétate de vinyle, qui sont mélangés pour créer un matériau avec des propriétés uniques. La combinaison de ces deux composés se traduit par une mousse douce, flexible, et résistant aux fissures et aux larmes. La mousse EVA peut être fabriquée dans diverses densités et épaisseurs pour répondre à différents besoins et exigences.

À quoi sert la mousse Eva pour?

Eva Foam est un matériau très polyvalent qui trouve des applications dans un large éventail d'industries. Il est couramment utilisé dans la production de tapis de sport, blocs de yoga, semelles de chaussures, et rembourrage protecteur. En plus, La mousse Eva est utilisée dans emballage pour protéger les articles fragiles Pendant l'expédition et la manipulation. Ses propriétés légères et absorbant les chocs en font un choix populaire pour Case de mousse Eva.

- Tapis de sport

- Blocs de yoga

- Semelles intérieures à chaussures

- Revêtements de casque, coussinets de genou, et les pads du coude

- Costumes de cosplay, fabrication de modèles, et décoration de bricolage

- Jouets pour enfants, puzzle, et jeux

- Inserts personnalisés pour protéger les éléments délicats

- Supports orthopédiques, rembourrage prothétique, et coussins en fauteuil roulant

- Panneaux d'insuffisance

- Tapis flottants

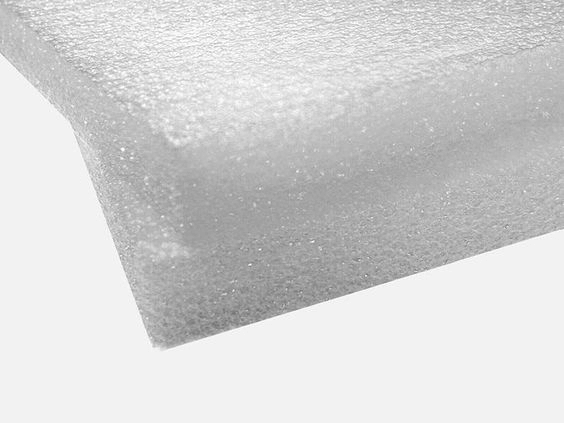

Qu'est-ce que la mousse PE?

Sur la mousse, ou mousse de polyéthylène, est un autre type de matériau en mousse qui est largement utilisé dans diverses industries. La mousse PE est une mousse à cellule fermée connue pour sa douceur et sa flexibilité. Il résiste aux produits chimiques et à l'humidité, Le rendre idéal pour les applications qui nécessitent une résistance et une durabilité. La mousse PE est couramment utilisée dans conditionnement, isolation, et applications d'amorti.

De quoi est fait de la mousse PE?

La mousse PE est faite de Polyéthylène, un matériau thermoplastique connu pour sa ténacité et sa flexibilité. La mousse de polyéthylène est créée en extrudant le polymère à travers une série de processus pour former un matériau en mousse avec une structure cellulaire uniforme. La mousse résultante est légère, doux, et résilient, Le rendre adapté à un large éventail d'applications.

À quoi sert la mousse PE pour?

La mousse PE est un matériau polyvalent utilisé dans une variété d'industries à différentes fins. Il est couramment utilisé dans conditionnement Fournir un amorti et une protection pour les articles délicats pendant le transport. La mousse PE est également utilisée dans le Industrie de la construction à des fins d'isolation En raison de ses propriétés thermiques et acoustiques. En outre, La mousse PE est utilisée dans le Industrie automobile pour l'isolation saine et l'amortissement des vibrations.

- Inserts d'emballage

- Feuilles d'isolation

- Matériau d'amorti

- Isolation du son automobile

- Isolation de tuyau

- Isolation du conduit HVAC

- Dispositifs de flottaison

- Emballage de protection

- Sous-couche pour les revêtements de sol

- Accolades médicales

EVA contre. Sur la mousse, Quelle est la différence?

Lorsque vous comparez la mousse Eva et la mousse PE, Il existe plusieurs différences clés qui les distinguent.

| Propriété | Mousse eva | Sur la mousse |

| Durabilité | Résistance supérieure aux fissures et aux larmes | Sujet aux perforations et aux larmes |

| Flexibilité | Haute flexibilité et douceur | Flexible mais légèrement moins souple |

| Résistance à l'eau | Modérément résistant à l'humidité | Résistant à l'humidité et n'absorbe pas l'eau |

| Absorption des chocs | Excellentes propriétés d'absorption des chocs | Bonnes capacités d'absorption des chocs |

| Résistance à la température | Peut résister aux températures de -20 ° C à 70 ° C | Peut résister à une large gamme de températures |

| Résistance chimique | Modérément résistant aux produits chimiques | Excellente résistance aux acides et aux alcalis |

| Coût | Un peu plus cher | Option plus abordable |

Comparaison de durabilité

En termes de durabilité, La mousse Eva et la mousse PE sont des matériaux résilients qui peuvent résister à l'usure régulière. Cependant, La mousse Eva est connue pour sa résistance supérieure aux fissures et aux larmes, En faire une option plus durable pour une utilisation à long terme. Sur la mousse, d'autre part, Peut être sujet aux perforations et aux larmes en raison de sa nature plus douce.

Test de flexibilité

En termes de flexibilité, La mousse Eva est connue pour sa haute flexibilité et sa douceur, ce qui le rend facile à façonner et à mouler en différentes formes. Sur la mousse, Bien que aussi flexible, Peut être légèrement moins souple que la mousse EVA, Le rendre mieux adapté aux applications qui nécessitent un matériel plus rigide. Les deux mousses peuvent être facilement coupées, courbé, et façonné pour répondre aux exigences spécifiques.

Résistance à l'eau

Quand il s'agit de résistance à l'eau, La mousse PE a le bord sur la mousse EVA en raison de sa structure à cellules fermées et de ses propriétés hydrophobes. La mousse PE est résistante à l'humidité et n'absorbe pas l'eau, En faire un choix idéal pour les applications qui nécessitent une protection contre les dommages causés par l'eau. Mousse EVA, tandis que la résistance à l'eau dans une certaine mesure, peut absorber l'humidité au fil du temps, le rendre moins adapté à une exposition prolongée à des conditions humides.

Absorption des chocs

La mousse EVA est réputée pour ses excellentes propriétés d'absorption des chocs, En faire un choix populaire pour les applications qui nécessitent une résistance à l'impact. La structure à cellules fermées de la mousse EVA lui permet de comprimer et de rebondir, absorber les chocs et protéger les objets délicats des dommages. La mousse PE offre également de bonnes capacités d'absorption de choc, mais peut ne pas être aussi efficace que la mousse EVA dans des situations à fort impact.

Résistance à la température

La mousse EVA et la mousse PE présentent une bonne résistance à la température, Désireux d'un large éventail de températures sans perdre leur forme ou leurs propriétés. La mousse EVA peut résister à des températures allant de -20 ° C à 70 ° C, Le rendre adapté aux applications extérieures et aux conditions météorologiques extrêmes. La mousse PE a une plage de température similaire, En faire un matériau polyvalent pour les applications qui nécessitent une stabilité thermique.

Résistance chimique

La mousse PE est connue pour son excellente résistance chimique, Le rendre idéal pour les applications qui impliquent une exposition à des produits chimiques et solvants durs. La mousse PE est résistante aux acides, alcalis, et autres substances corrosives, ce qui en fait un choix fiable pour le stockage et le transport chimiques. Mousse EVA, Bien que modérément résistant aux produits chimiques, peut être sujet à la dégradation lorsqu'il est exposé à certains solvants et acides.

Comparaison des coûts

En termes de coût, La mousse PE est généralement plus abordable que la mousse EVA en raison des différences dans les processus de fabrication et les coûts de matières premières. La mousse PE est une option rentable pour les applications qui nécessitent un amorti et une isolation sans avoir besoin d'une résistance à fort impact. Mousse EVA, Bien que légèrement plus cher, offre une absorption et une durabilité de choc supérieures, En faire un choix préféré pour les applications qui exigent des matériaux en mousse haute performance.

Mousse eva vs. Sur la mousse: Quel est le meilleur?

Le choix entre Eva Foam et PE Foam dépend en fin de compte des besoins spécifiques de votre projet. Si vous avez besoin d'une absorption de choc et d'un amorti supérieurs pour des applications à fort impact, La mousse Eva peut être la meilleure option. Cependant, Si la résistance à l'eau et la résistance chimique sont des considérations clés pour votre projet, La mousse PE peut être le choix préféré.

Coclusion

En conclusion, La mousse EVA et la mousse PE sont deux matériaux polyvalents qui offrent des propriétés et des avantages uniques pour un large éventail d'applications. La mousse EVA est évaluée à ses propriétés d'absorption de choc et d'amorti, Le rendre idéal pour l'équipement sportif, rembourrage de protection, et fabriquer des applications. Sur la mousse, d'autre part, est connu pour sa résistance à l'eau et sa résistance chimique, Le rendre adapté à l'emballage, isolation, et applications d'amorti. Lors du choix entre la mousse EVA et la mousse PE, Considérez les exigences spécifiques de votre projet et sélectionnez le matériau en mousse qui répond le mieux à vos besoins.