EVA Case for Optical Device

An optical professional or enthusiast knows how precise and valuable their instruments are. That’s why our EVA carrying cases are essential for keeping your optical devices safe, organized, and ready for use anywhere.

Our cases are designed to fit a wide range of premium optical equipment, including:

Camera and lens cases

Binocular and rangefinder cases

Microscope and optical sensor cases

Night vision and thermal imaging device cases

With a perfect balance of lightweight structure and custom-fit protection, our optical device carrying cases ensure your delicate instruments stay secure from impact, dust, and moisture—wherever your work takes you.

Explore Our Custom EVA Cases for Optical Device

Elevating Protection

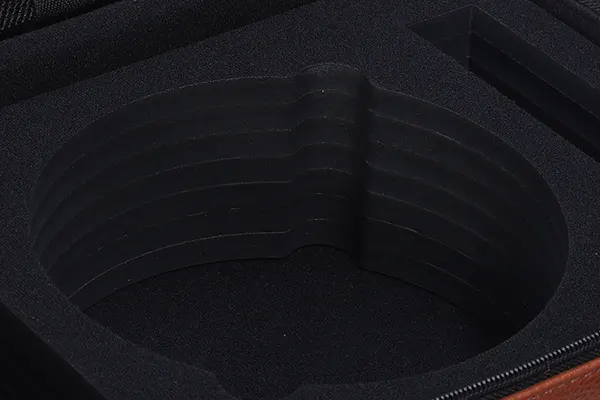

When it comes to optical device, a high-quality EVA carrying case should never compromise on its inner design.

At KinFish Case, we understand the importance of protecting your clients’ valuable equipment. That’s why our carrying cases are designed with multiple thick and soft layers to ensure maximum safety.

In addition, our versatile foam styles can be tailored to fit each unique piece of optical equipment.

Built-to-last Design

Optical device can be expensive and fragile, and professionals want to carry cases that can withstand the wear and tear of frequent transport and storage.

Made of durable and high-quality materials, our custom EVA cases ensure that they can withstand the rigors of the road and protect equipment over the long term.

Remind Customers of Their Passions

Optical Device brands want carrying cases that align with their branding and style needs. EVA carrying cases can be designed with custom shapes, sizes, and colors, as well as branding elements such as logos and messaging.

This allows Optical Device brands to stand out in a crowded market and create a cohesive brand image across their equipment and carrying cases.

No Matter Where the Passion Takes Them to

Your Optical Device deserves the best in carry cases. For Optical Device pros on the move, lightweight and easy-to-transport cases are key. KinFish Case’s EVA carrying cases fit the bill, complete with comfortable handles and shoulder straps for added convenience and comfort.

Case Study

Custom Optical Device Case

Challenges

- Protecting delicate optical instruments requires a case that offers both structural rigidity and precision cushioning. The client requested a lightweight yet impact-resistant case with a customized interior tailored to the lens and device contours. Additionally, the design needed to incorporate dustproof protection, fingerprint-resistant textures, and a professional look suited for field-use optical equipment.

Another challenge was ensuring quick access and secure closure—the case had to open smoothly without disturbing the stored device, while maintaining a compact, travel-friendly size.

Solutions

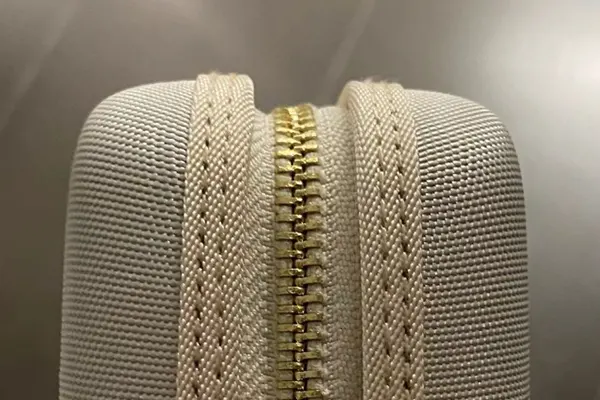

- We developed a thermoformed EVA shell structure combined with a custom-cut foam insert to match the exact shape of the optical device, ensuring both shock absorption and stability.

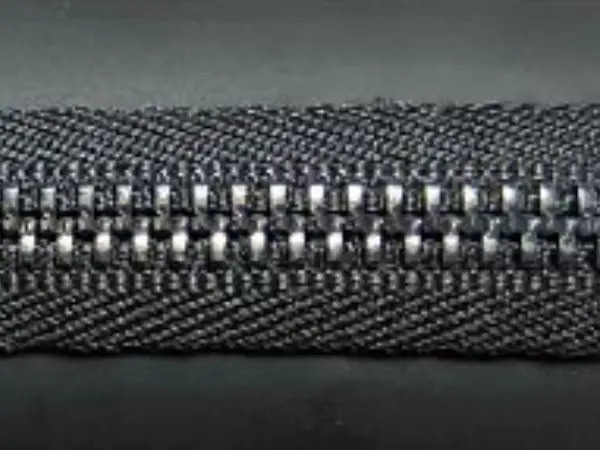

- To enhance security and convenience, we integrated a reinforced zipper system engineered for smooth operation and long-term reliability.

Take a Closer Look at How Each of the Processes Work

Raw Material

Before manufacturing, we will source qualified materials from trustworthy factories. These raw materials can include EVA foam sheets, fabrics, zippers, and other hardware items.

Laminating

In this step, our workers will laminate together EVA sheet with exterior material and interior material using eco-friendly adhesive.

Cutting

The laminated material is then cut into the required size and shape using a cutting machine. Precise and accurate cutting makes the pieces assembling process more easily.

Pre-heating

The cut pieces will be pre-heated so that they are pliable and easy to mold.

Thermoforming

Then, with the mold having been carefully designed to the demanded shape and size, an automotive molding machine will create the precise shape.

Trimming

After molding, excess material is trimmed off using a die-cut machine. In that way, the EVA shell looks clean and tidy.

Stitching

Then, our craftsmen will carefully stitch the different pieces together using a sewing machine. This step ensures that the case is strong and durable.

Inspection

All of the products that come out of our hands have gone under 100% inspection. Any defects are identified and corrected at this stage.

Packaging

Once the inspection is complete, you can happily wait for your EVA cases that are carefully packaged.

Got Your Own Solution in Mind?

We’d love to hear from you about your vision. Let us collaborate to develop the best eva case solution for your business.

What Makes Us Different from Other Manufacturers?

Mature Control of Craftsmanship Details

We place great emphasis on every step of the process, such as sewing, manual assembly, special zipper techniques, molding, and more. With customized EVA case samples, you can experience our craftsmanship more vividly.

Strict Material Quality Inspection

We use high-quality high-density 75-degree 6mm EVA as the core raw material, enabling the design of more durable hard shell EVA cases.

Professional Design Assistance

We offer professional capabilities in crafting branded EVA cases. Feel free to share your design ideas with us, and together, we can create a high-end EVA case that showcases your brand.

Customization Options

There is a portfolio of accessories for your selections. Every detail can be customized to visualize and improve your brand recognition.

Learn About Our Custom EVA Case Cooperative Process

Consultation & Discovery

Hola! We’re expecting you. Let’s get to know a little bit about each other.

To better understand your unique needs for the EVA case, we can always schedule a video call.

This allows us a more tailored and efficient consultation – we can discuss the case’s purpose, size, shape, materials, and other necessary details like face to face. By this, we can we design and manufacture a product that meets your specific requirements and exceeds your expectations.

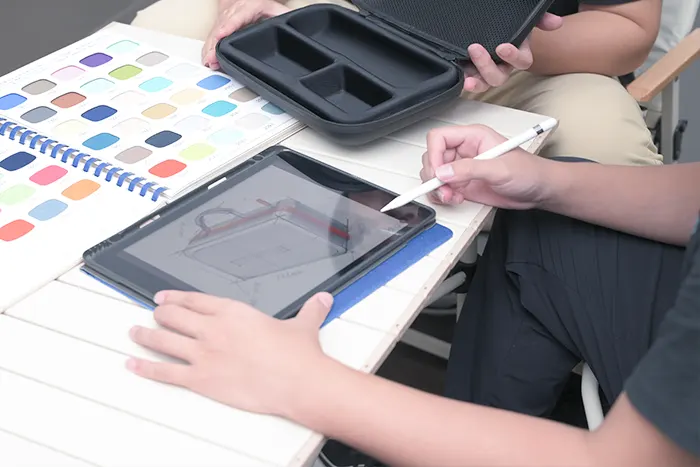

Getting Ready to Design

Hold on, don’t rush yet. We just know each other.

Before we start designing, we may need to sign a non-disclosure agreement(NDA) to protect each of our confidential information.

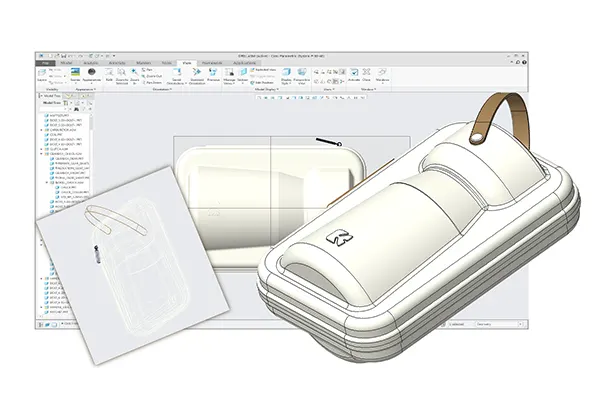

We create simple drawings and 2D renderings of the case based on the information gathered during the discovery phase. This helps you visualize the product and make any necessary changes before we proceed to the 3D model.

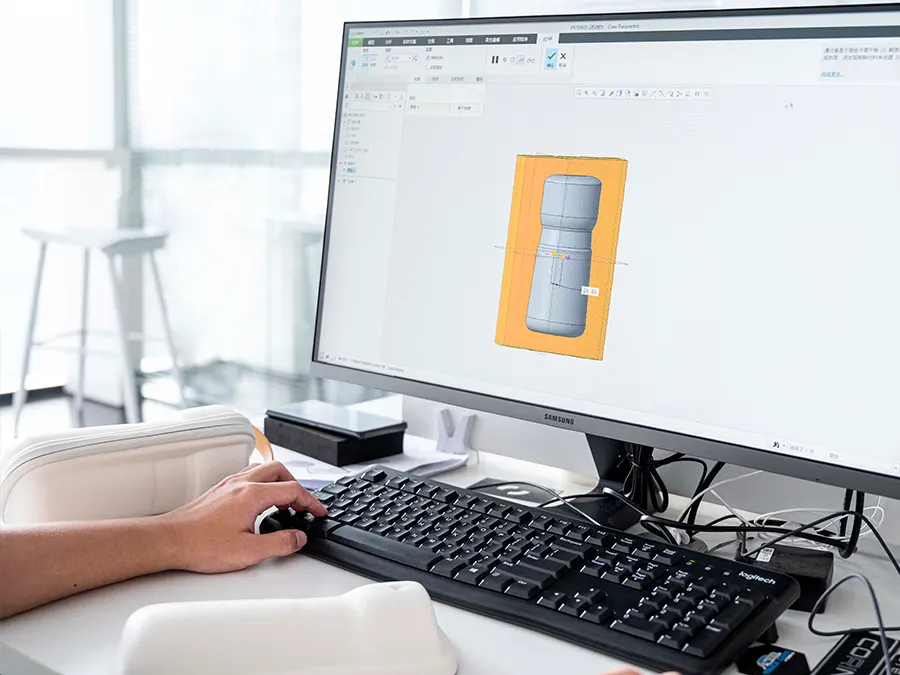

Presentation

Now I guess it’s the phase we both agree on something.

Our team creates a detailed 3D model of the EVA case. By checking the 3D model, you can make any final changes before we move on to the tooling phase

We offer free design services and aim to provide the initial design within 2 days.

Tooling

Now let’s make it happen.

We create the tooling necessary to shape the EVA case. Our team ensures that the tooling meets our high standards for precision and durability. In 5 to 7 days, you will meet it.

Prototype

Ready to meet our artwork?

We begin your custom molded case building and sample production. This allows us to create a prototype of the EVA case and test it for fit, functionality, and durability. If necessary, we make any adjustments before proceeding to mass production.

Mass Production

Woah! There are so many of them.

Once the prototype is approved, we move on to the manufacturing process. Our experienced workers will carefully produce your EVA cases using a range of techniques, including laminating, cutting, thermoforming, stitching, trimming, etc. High-quality materials and state-of-the-art machinery ensure precision and durability.

From start to finish, we closely monitor each step of the manufacturing process to ensure the quality of your products.

100% Thorough Inspection

Attention please, none of them gets to escape.

A rigorous inspection and testing process, from appearance to the smallest accessories on the inside or outside, will be conducted to ensure that each custom EVA case meets our standards for quality and functionality. By 100% inspection, we really mean it.

Delivery

Voila! You got them.

For bulk production, it takes around one month for you to receive your custom EVA cases. We understand that timely delivery is critical, and we’ll work to ensure that you receive your cases on time and in good condition. We’re committed to providing excellent customer service and support throughout the entire process.