إن تصميم علبة EVA عالية الجودة هو أكثر من مجرد اختيار غلاف وإضافة سحاب. إنها عملية هندسية إبداعية تمزج بين الحماية, جماليات, وتجربة المستخدم في حزمة واحدة مدمجة. سواء كنت تقوم ببناء علبة EVA مخصصة للإلكترونيات, الأدوات الطبية, أجهزة التجميل, أو المنتجات الاستهلاكية المتميزة, كل التفاصيل مهمة. بالتخطيط الصحيح والصحيح قضية إيفا مزود, حالتك يمكن أن ترفع قيمة منتجك, زيادة مصداقية العلامة التجارية, وضمان المتانة في العالم الحقيقي.

في هذا الدليل, سنوجهك عبر الاعتبارات الخمسة الرئيسية التي يجب أن تضعها في اعتبارك عند تصميم حقيبة EVA - والتي سيتم توسيع كل منها إلى عملية, أقسام سهلة المتابعة، بالإضافة إلى الأسئلة الشائعة لمساعدتك على الفهم بشكل أفضل إيفا كمادة.

حدد الغرض وحالات الاستخدام الخاصة بحالة النشاطات خارج المركبة (EVA).

يبدأ التصميم الناجح لحالة EVA بالوضوح. قبل الرسم أو النماذج الأولية, عليك أن تفهم تمامًا ما ينبغي أن تكون عليه الحالة يفعل و من هذا هو الحال بالنسبة.

ما هو المنتج الذي ستحميه هذه الحالة?

- تقييم حجم المنتج, شكل, وزن, والهشاشة. الأجهزة ذات الشاشات, العدسات, أو تتطلب الزوايا الحادة إدارة إضافية للصدمات.

- فكر فيما إذا كان المنتج يحتاج إلى حماية ثابتة, العزل المائي, مقاومة الحرارة, أو تخطيطات مقصورة مخصصة.

- تحديد ما إذا كانت الملحقات والشواحن, الكابلات, الأدلة - يجب تخزينها معًا أو بشكل منفصل.

من سيستخدم حقيبة إيفا هذه?

- المستخدمين المحترفين (طبي, صناعي, أو المجالات التقنية) توقع المتانة, مقاومة التأثير, والتخزين المنظم.

- المستهلكون يقدرون المظهر, قابلية النقل, والراحة.

- يحتاج تغليف التجزئة إلى علامة تجارية قوية, القوام المتميز, وهيكل مثير للإعجاب بصريا.

كيف وأين سيتم استخدام هذه الحالة?

- تتطلب البيئات الخارجية أو بيئات السفر قذائف أقوى, مقاومة الرش, وخيارات حمل سهلة.

- تعطي البيئات الداخلية أو خفيفة الاستخدام الأولوية للجماليات والتصميم خفيف الوزن.

- للإلكترونيات المتميزة, مساحات داخلية ناعمة الملمس, والتشطيبات المصقولة تعزز تجربة المستخدم.

اختر صلابة EVA المناسبة, كثافة & سماكة

يتم تحديد الأداء الوقائي لحالة EVA إلى حد كبير من خلال الخصائص الفيزيائية لطبقة EVA. محترف شركة EVA Case Manufaction سوف تساعدك على اختيار التوازن الصحيح.

صلابة إيفا (50-80 شور ج)

- توفر الصلابة المنخفضة مرونة خفيفة الوزن, مثالية للأزياء أو منتجات التجميل.

- توفر الصلابة العالية غلافًا واقيًا صلبًا للإلكترونيات, الآلات, أو الأدوات.

- غالبًا ما تُفضل الصلابة المتوسطة للمنتجات التي تتطلب الراحة والمتانة.

الكثافة والقوة الهيكلية

- تعمل الكثافة العالية على تحسين مقاومة الضغط والحفاظ على الشكل.

- توفر الكثافة المنخفضة توسيدًا أكثر نعومة ولكنها قد تتشوه مع الضغط الثقيل على المدى الطويل.

- مزيج من مادة EVA عالية الكثافة + مادة EVA الناعمة بالداخل — شائعة في الأجهزة الحساسة.

اعتبارات سمك الجدار

- إيفا أكثر سمكا (5-7 ملم) مثالي للمعدات الخارجية, الأجهزة الصناعية, أو حساس طبي أدوات.

- سمك قياسي (3-5 ملم) يعمل لمعظم المنتجات الاستهلاكية.

- إيفا سليم (أقل 3 مم) مناسب للحالات خفيفة الوزن أو الملائمة للسفر.

طوّر تصميمًا داخليًا عمليًا وسهل الاستخدام

التصميم الخارجي الجميل لا يعني شيئًا إذا كان التصميم الداخلي لا يحمي المنتج أو يدعم سهولة الاستخدام. الهيكل الداخلي أمر بالغ الأهمية.

حشوات إسفنجية مقطوعة باستخدام الحاسب الآلي

- يوفر تحديدًا دقيقًا للمنتج للحصول على أقصى قدر من امتصاص الصدمات.

- يمنع الحركة أثناء النقل, تقليل مخاطر الضرر.

- مثالي للأجهزة الهشة مثل الكاميرات, أدوات التشخيص, أو إلكتروني متر.

جيوب شبكية أو بسحاب

- رائعة لتنظيم الملحقات دون إضافة حجم كبير.

- يحسن سهولة الاستخدام من خلال الحفاظ على سهولة الوصول إلى العناصر الصغيرة.

- مثالي للمنتجات التي تتضمن كابلات أو ملحقات متعددة.

الأشرطة المرنة والفواصل

- يساعد على تأمين العناصر ذات الأشكال والأحجام المختلفة.

- شائع في مجموعات الأدوات, مجموعات طبية, ومعدات السفر.

- يسمح بتخطيطات مرنة دون قطع الرغوة المخصصة.

تصميم متعدد الطبقات أو وحدات

- مناسبة للمجموعات ذات المكونات المتعددة.

- يحسن التنظيم ويعزز الشعور المهني بالقضية.

- يدعم ترقيات المنتج المستقبلية أو إصدارات الملحقات الجديدة.

حدد المادة الخارجية, أسلوب & هوية العلامة التجارية

يعكس الجزء الخارجي لحافظة EVA شخصية علامتك التجارية. تعمل القشرة ذات المظهر الاحترافي على تعزيز ثقة العملاء على الفور.

خيارات المواد السطحية

- بو الجلود: مظهر متميز للإلكترونيات وأجهزة التجميل المتطورة.

- بوليستر/نايلون: مقاومة للتآكل, مثالية للاستخدام في الهواء الطلق أو الصناعي.

- إيفا محكم: حديثة وبسيطة مع متانة ممتازة.

- تشطيبات مطاطية: توفر قبضة ناعمة الملمس وشعورًا فاخرًا.

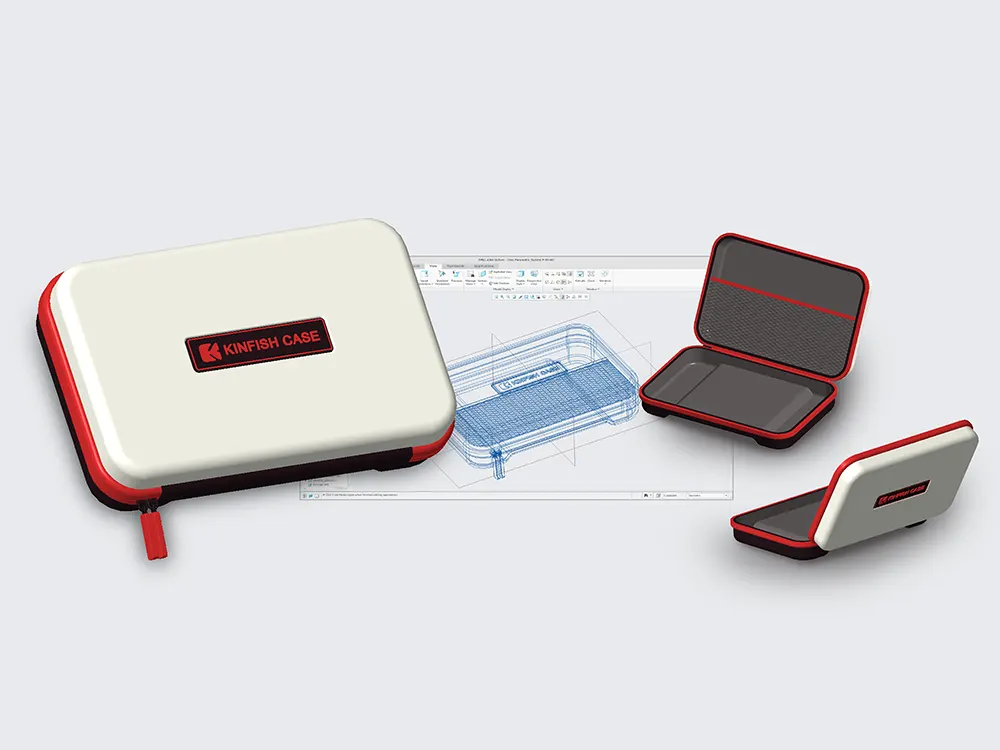

عناصر العلامة التجارية المخصصة

- أضف شعار علامتك التجارية عبر النقش, النقش, بقع, الطباعة, أو شارات معدنية.

- يعمل تنسيق الألوان المتسق على تعزيز التعرف على العلامة التجارية وجاذبية الرف.

- لهجات عالية التباين (السوستة, الديكورات, خياطة) تحسين التمايز البصري.

مكونات الأجهزة

- السوستة: النظر في للماء, انزلاق سلس, أو سحابات كبيرة الحجم للاستخدام الشاق.

- مقابض وأشرطة: أحزمة المعصم, أحزمة الكتف, والمقابض المصبوبة تزيد من سهولة الحمل.

- لوحة الاسم الداخلية أو نافذة الهوية: مفيدة للشركات, طبي, أو تأجير المعدات.

تقييم الشركة المصنعة الخاصة بك, عملية & كفاءة التكلفة

أفضل تصميم لا يكون إلا بجودة الفريق الذي يصنعه. يضمن اختيار مورد محترف لحالات إيفا جودة ثابتة وموثوقية طويلة المدى.

قدرة المورد والخبرة

- ابحث عن المصانع المتخصصة في حالات EVA المخصصة, ليس صانعي الأكياس العامة.

- تحقق من أمثلة المحفظة في صناعتك - الطبية, جمال, الإلكترونيات, إلخ.

- اسأل ما إذا كانوا يقدمون تطويرًا داخليًا للقالب وخدمات OEM/ODM كاملة.

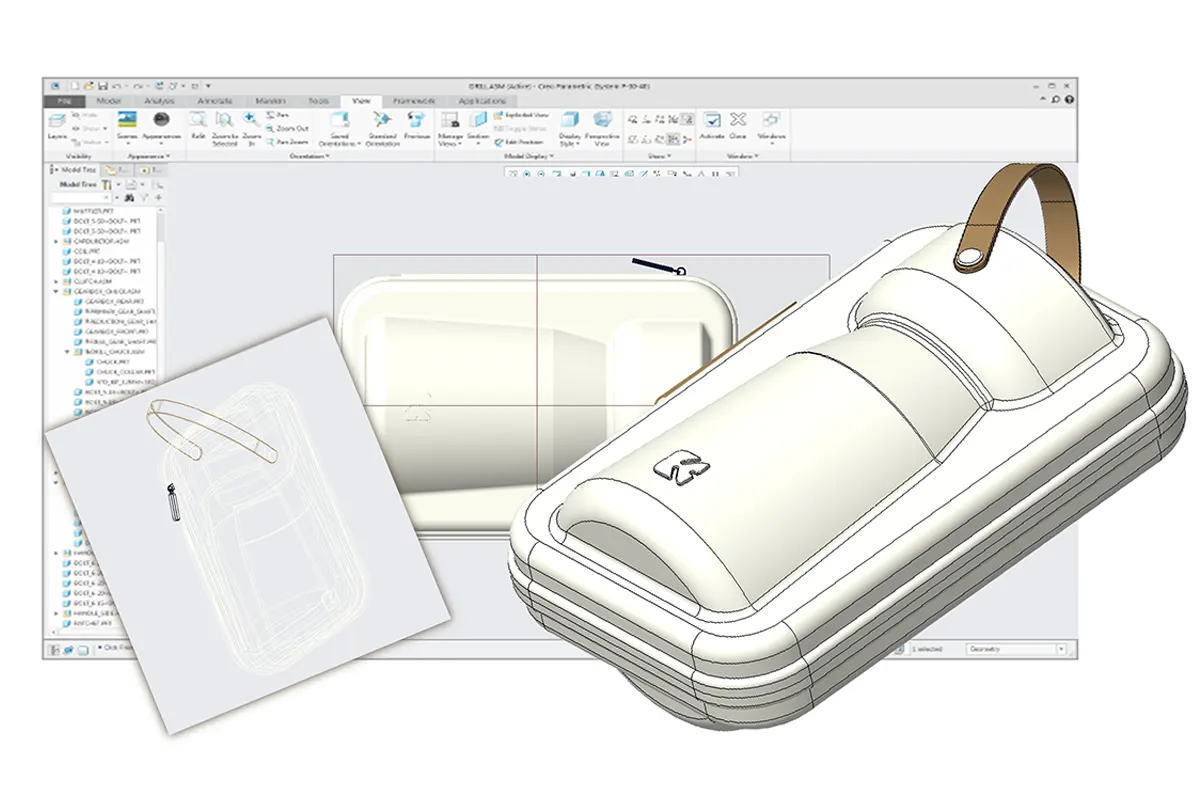

الاتصالات والنماذج سير العمل

- تقدم الشركة المصنعة الجيدة رسومات التصميم, خيارات المواد, واقتراحات النماذج الأولية.

- اطلب عينة ما قبل الإنتاج لتأكيد كل التفاصيل قبل الإنتاج الضخم.

- يمنع الاتصال الواضح عمليات إعادة التصميم والتأخير المكلفة.

ضبط الجودة, مهلة & عوامل التكلفة

- تأكيد معايير التفتيش (اختبارات السقوط, السوستة, طبقات, الترابط الغراء).

- فهم جداول الإنتاج, خاصة بالنسبة للقوالب المخصصة.

- تقييم تكاليف المواد, الطباعة, رسوم العفن, والأدوات.

الأسئلة الشائعة حول مادة EVA

ما هي حماية إيفا?

تشير حماية EVA إلى قدرة رغوة أسيتات فينيل الإيثيلين على امتصاص الصدمات, مقاومة الضغط, وحماية العناصر من الصدمات أو الضغط. طبيعتها شبه الصلبة توزع القوة بالتساوي, مما يجعلها مثالية ل حالات EVA المخصصة, التعبئة والتغليف الواقية, معدات رياضية, والمساكن الالكترونيات.

هو إيفا 100% ضد للماء?

مادة EVA مقاومة للماء ولكنها ليست مقاومة للماء تمامًا.

ال رغوة إيفا في حد ذاته لا يمتص الماء, لكن الدرزات المخيطة أو مناطق السحاب قد تسمح بدخول الرطوبة. للتطبيقات الخارجية, تعمل السحابات المقاومة للماء أو الطبقات المختومة على تحسين الحماية.

ما هي خصائص المواد إيفا?

- خفيفة الوزن وسهلة التشكيل في أشكال معقدة

- امتصاص ممتاز للصدمات ومقاومة الصدمات

- مقاومة للرطوبة, المواد الكيميائية, والتعرض للأشعة فوق البنفسجية

- متوفر بكثافات متعددة, الألوان, وينتهي

- متينة ولكنها مرنة, مما يجعلها مناسبة للعديد من الصناعات

هذه الخصائص تجعل EVA واحدة من المواد الأكثر استخدامًا على نطاق واسع لتصنيع الأغطية الواقية, خاصة بين الشركات المصنعة لحالات EVA المحترفة.

خاتمة: تساعدك حقيبة KF على إضفاء الحيوية على أفكار حقيبة EVA الخاصة بك

يعد تصميم علبة EVA عملية إبداعية وتقنية تمزج بين الحماية, مظهر, وسهولة الاستخدام. من خلال فهم احتياجات المنتج الخاص بك, اختيار مواصفات EVA المناسبة, التخطيط لتخطيط داخلي ذكي, واختيار المواد التي تعكس علامتك التجارية, يمكنك إنشاء حالة تعزز حقًا قيمة منتجك.

إذا كنت على استعداد لتحويل أفكارك إلى واقع, حالة EVA جاهزة للسوق, KF Case هنا للمساعدة. كشركة مصنعة لحالة إيفا من ذوي الخبرة, نحن نقدم خدمات OEM/ODM كاملة, النماذج الأولية المهنية, مواد ذات جودة عالية, والإنتاج الضخم الموثوق به. سواء كنت بحاجة إلى علبة إلكترونية صغيرة الحجم أو حل صناعي مخصص بالكامل, يمكننا دعم مشروعك من الفكرة إلى الاكتمال.

👉 تعرف على المزيد أو اتصل بنا اليوم: https://kfcase.com/