EVA Case for Sports & Outdoors Overview

Looking to outfit your brand with high-quality gear that can withstand even the most rugged outdoor activities?

Specifically designed to protect your gear from even the toughest conditions, custom EVA cases that are protective, including

- helmet case

- fishing gear

- ski goggle case

- EDC tools

- watch case

- bottle case

- massage gun case

- …

These cases are perfect for athletes, outdoor enthusiasts, and anyone who needs to transport valuable equipment. Reach us for custom EVA carrying cases which provide unparalleled protection and storage.

Explore Our Custom EVA Cases for Sports & Outdoors

Stay Connected with Sports & Outdoor Trends

For KinFish Case, there is no better way than getting to know your brands in your place, your time. And that’s one of the ways we build satisfying products.

We take great joy in sharing our journey of exploration through our regular presence at OR exhibitions, the biggest sports and outdoor marketing event in North America. Join us on this extraordinary adventure and elevate your sports brands to new heights.

Denver, Colorado, U.S.

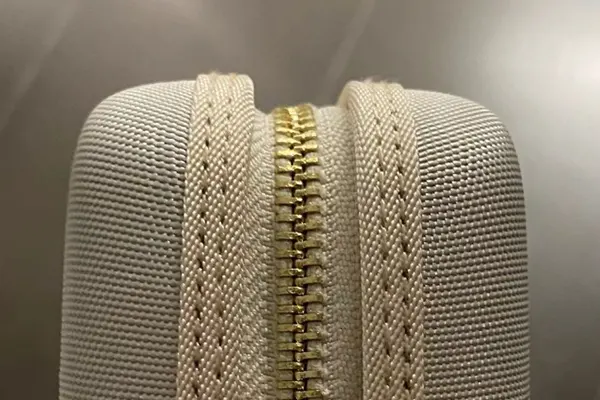

Sleek, Impeccable, Durable Every Piece of Fabric Works.

Every piece of fabric is carefully choosen, and they work together to create a lines of EVA case products that are resistant to wear and tear. They survive even the most rugged outdoor activities.

But durability doesn’t mean sacrificing style or comfort. Designed to be sleek and impeccable, our products ensure that your clients look and feel their best no matter where their adventures take them.

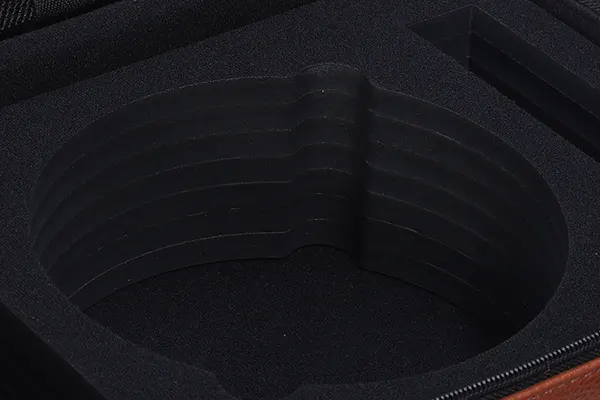

Stay in Place. Resilient & Resistant

Designed to keep your gear safe and organized no matter where your adventures take you, our state-of-the-art molding capabilities allow us to create custom shapes and compartment designs tailored to your specific needs.

From motorcycle helmets to sensitive electronic equipment, our customizable foam inserts provide added protection and peace of mind for you and your customers.

Upgrade Storage Capabilities

Soft EVA carrying case can exceed your expectation. With limitless potential, you can take your brand to new heights by providing your clients with innovative and functional designs.

Waterproof

It is possible to create a waterproof case using a range of techniques, including zipperless designs and even designs without any sewing holes. Regardless of the methodology used, a waterproof case can be achieved.

Heat Preservation

Our innovative design keeps ice and other frozen items cold for hours on end. Durable construction and insulating materials make it a must-have for any outdoor enthusiast.

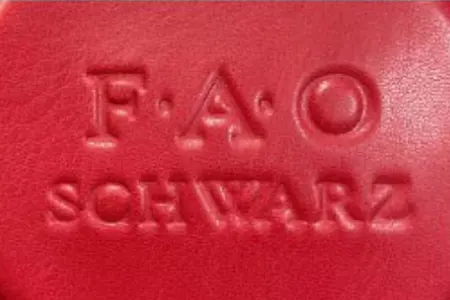

Keep Your Brand Image Stand-out

When it comes to sports and outdoor activities, having a strong and recognizable brand image can make a real difference. Select from our high-quality materials, which include premium fabrics, assisted metals, and sturdy plastics that can withstand even the toughest outdoor environments.

Our team of experts will work with you to create unique, stand-out designs that leave a lasting impression on your customers. Don’t just settle for generic products, let us help you elevate your brand and make it shine!

Case Study

Custom EVA Case with Heat Preservation

Challenges

- The products consist of a pair of compression leggings and four ice packs.

- The carrying case must be able to keep ice packs cold for hours.

- There should be a flap for the bottom shell, which provides seperate compartments for the ice packs and leggings.

Solutions

- For interior material, we employ insulated materials, as well as combining EPE foam, to optimize the thermal effect.

- Add a pocket above the bottom shell. Inside the pocket, EPE foam works as a middle layer, with a zipper above. Our test confirms that this EVA carry case can keep the ice packs cold for up to 6 hours!

Take a Closer Look at How Each of the Processes Work

Raw Material

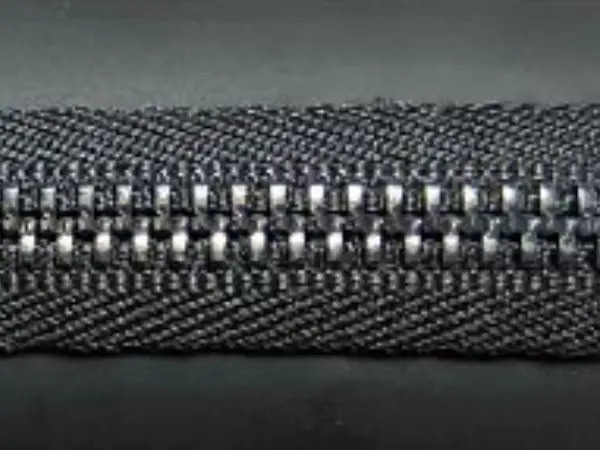

Before manufacturing, we will source qualified materials from trustworthy factories. These raw materials can include EVA foam sheets, fabrics, zippers, and other hardware items.

Laminating

In this step, our workers will laminate together EVA sheet with exterior material and interior material using eco-friendly adhesive.

Cutting

The laminated material is then cut into the required size and shape using a cutting machine. Precise and accurate cutting makes the pieces assembling process more easily.

Pre-heating

The cut pieces will be pre-heated so that they are pliable and easy to mold.

Thermoforming

Then, with the mold having been carefully designed to the demanded shape and size, an automotive molding machine will create the precise shape.

Trimming

After molding, excess material is trimmed off using a die-cut machine. In that way, the EVA shell looks clean and tidy.

Stitching

Then, our craftsmen will carefully stitch the different pieces together using a sewing machine. This step ensures that the case is strong and durable.

Inspection

All of the products that come out of our hands have gone under 100% inspection. Any defects are identified and corrected at this stage.

Packaging

Once the inspection is complete, you can happily wait for your EVA cases that are carefully packaged.

Got Your Own Solution in Mind?

We’d love to hear from you about your vision. Let us collaborate to develop the best eva case solution for your business.

What Makes Us Different from Other Manufacturers?

Mature Control of Craftsmanship Details

We place great emphasis on every step of the process, such as sewing, manual assembly, special zipper techniques, molding, and more. With customized EVA case samples, you can experience our craftsmanship more vividly.

Strict Material Quality Inspection

We use high-quality high-density 75-degree 6mm EVA as the core raw material, enabling the design of more durable hard shell EVA cases.

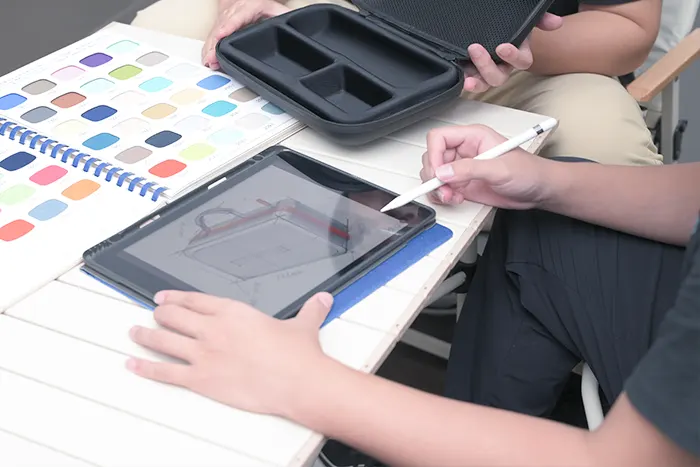

Professional Design Assistance

We offer professional capabilities in crafting branded EVA cases. Feel free to share your design ideas with us, and together, we can create a high-end EVA case that showcases your brand.

Customization Options

There is a portfolio of accessories for your selections. Every detail can be customized to visualize and improve your brand recognition.

Learn About Our Custom EVA Case Cooperative Process

Consultation & Discovery

Hola! We’re expecting you. Let’s get to know a little bit about each other.

To better understand your unique needs for the EVA case, we can always schedule a video call.

This allows us a more tailored and efficient consultation – we can discuss the case’s purpose, size, shape, materials, and other necessary details like face to face. By this, we can we design and manufacture a product that meets your specific requirements and exceeds your expectations.

Getting Ready to Design

Hold on, don’t rush yet. We just know each other.

Before we start designing, we may need to sign a non-disclosure agreement(NDA) to protect each of our confidential information.

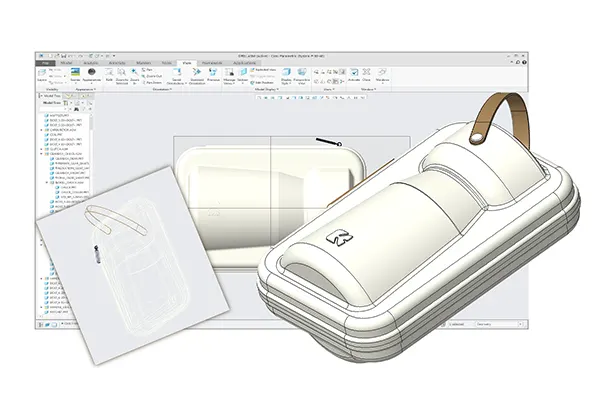

We create simple drawings and 2D renderings of the case based on the information gathered during the discovery phase. This helps you visualize the product and make any necessary changes before we proceed to the 3D model.

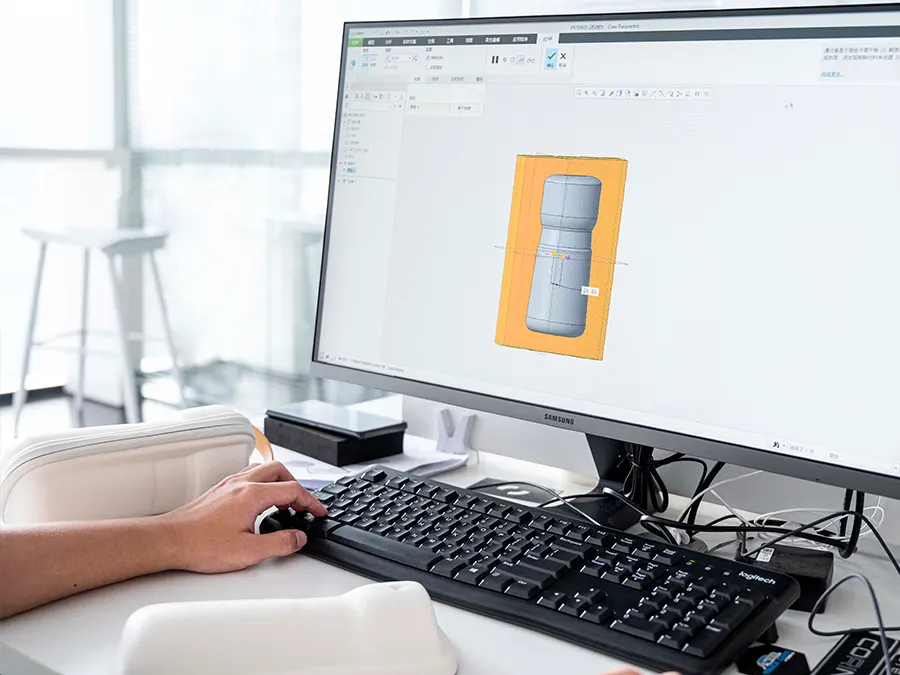

Presentation

Now I guess it’s the phase we both agree on something.

Our team creates a detailed 3D model of the EVA case. By checking the 3D model, you can make any final changes before we move on to the tooling phase

We offer free design services and aim to provide the initial design within 2 days.

Tooling

Now let’s make it happen.

We create the tooling necessary to shape the EVA case. Our team ensures that the tooling meets our high standards for precision and durability. In 5 to 7 days, you will meet it.

Prototype

Ready to meet our artwork?

We begin your custom molded case building and sample production. This allows us to create a prototype of the EVA case and test it for fit, functionality, and durability. If necessary, we make any adjustments before proceeding to mass production.

Mass Production

Woah! There are so many of them.

Once the prototype is approved, we move on to the manufacturing process. Our experienced workers will carefully produce your EVA cases using a range of techniques, including laminating, cutting, thermoforming, stitching, trimming, etc. High-quality materials and state-of-the-art machinery ensure precision and durability.

From start to finish, we closely monitor each step of the manufacturing process to ensure the quality of your products.

100% Thorough Inspection

Attention please, none of them gets to escape.

A rigorous inspection and testing process, from appearance to the smallest accessories on the inside or outside, will be conducted to ensure that each custom EVA case meets our standards for quality and functionality. By 100% inspection, we really mean it.

Delivery

Voila! You got them.

For bulk production, it takes around one month for you to receive your custom EVA cases. We understand that timely delivery is critical, and we’ll work to ensure that you receive your cases on time and in good condition. We’re committed to providing excellent customer service and support throughout the entire process.