Creating a high-quality custom EVA case involves far more than simply molding foam. It’s a structured manufacturing workflow that blends engineering, material science, craftsmanship, brand customization, and precise equipment operation. Whether you’re preparing for a new product launch or researching custom case manufacturing, this guide will help you understand every step behind the scenes—from raw materials all the way to final packaging.

What Are the Raw Materials of the EVA Case?

EVA (Ethylene Vinyl Acetate) is the core material used to build EVA cases. Its properties—like softness, rigidity, flexibility, and shock-absorption—are all determined by the quality and ratio of raw ingredients.

Ethylene: Provides Toughness & Structural Integrity

- Ethylene forms the backbone of EVA resin, giving the foam strength and impact resistance.

- It determines how well the case retains its shape even when exposed to pressure or impact.

- Higher ethylene content generally makes the foam firmer—ideal for tool cases, electronics kits, and industrial gear.

- It also contributes to long-term durability, preventing deformation during repeated use.

Vinyl Acetate (VA): Controls Softness & Elasticity

- VA content is responsible for EVA’s softness and flexibility.

- Higher VA ratios create softer, more cushioned foam suitable for fragile products.

- The VA level affects how “springy” and shock-absorbing the compression molded foam becomes.

- Industries like medical devices, audio equipment, and cosmetics often prefer mid or high VA levels.

Functional Additives: Tailoring EVA for Specialized Needs

- Foaming agents help EVA expand during molding, creating a lightweight yet protective cellular structure.

- Color masterbatch lets brands match their precise color palette for a more customized design.

- UV stabilizers prevent fading when cases are used outdoors.

- Antistatic, antibacterial, or flame-retardant additives are added depending on industry regulations.

- These ingredients ensure the EVA case meets both functional and branding requirements.

How to Make an EVA Case? (Step-by-Step Manufacturing Process)

Below is a detailed walkthrough of how a professional eva case manufacturer builds a high-performance EVA case from scratch.

| Step | Description |

| 1. Raw Material | Source qualified EVA foam sheets, fabrics, zippers, and hardware from trusted suppliers. |

| 2. Laminating | Bond EVA sheets with exterior and interior materials using eco-friendly adhesive. |

| 3. Cutting | Cut laminated materials into precise sizes and shapes for easier assembly. |

| 4. Pre-heating | Heat the cut pieces to make them pliable and ready for molding. |

| 5.Thermoforming | Mold the pre-heated pieces into the desired shape using an automotive molding machine. |

| 6. Trimming | Remove excess material with a die-cut machine to create a clean, tidy EVA shell. |

| 7. Stitching | Carefully stitch the pieces together to ensure durability and strength. |

| 8. Inspection | Conduct 100% quality checks to identify and correct any defects. |

| 9. Packaging | Carefully package the finished EVA cases for delivery. |

1. Raw Material Sourcing & Quality Control

Sourcing EVA Sheets, Fabrics, Zippers & Hardware

- The manufacturing process starts with sourcing premium EVA sheets from reputable suppliers.

- Fabrics—such as polyester, PU leather, nylon, or woven textiles—are selected based on brand requirements.

- Zippers, pullers, logo patches, and accessory hardware are checked for durability and consistency.

- Only materials that pass quality control enter the next phase, ensuring the final custom EVA case is reliable and long-lasting.

Why Material Quality Matters

- High-quality EVA provides better impact resistance and shape stability.

- Premium fabrics improve water resistance and aesthetic appeal.

- Reliable zippers reduce failure rates during long-term use.

- Consistent raw materials ensure color and texture match across large orders.

2. Laminating EVA With Outer & Inner Materials

Eco-Friendly Lamination Process

- Workers laminate EVA sheets with both the exterior fabric and interior lining using low-VOC, eco-friendly adhesives.

- This process bonds the three layers—outer fabric, EVA foam, inner lining—into a single composite structure.

- Proper lamination ensures the surface is smooth, wrinkle-free, and resistant to peeling.

- The quality of this step directly affects the case’s durability and appearance.

Benefits of High-Precision Lamination

- Prevents bubbles or uneven surfaces during molding.

- Enhances abrasion resistance and water repellence.

- Strengthens the bond between layers, ensuring long-term durability.

- Supports full customization, including printing and logo placement.

3. Cutting the Laminated Materials

Precision Cutting for Perfect Assembly

- The laminated sheets are cut into specific shapes using automatic cutting machines or die-cut tools.

- Accurate cutting ensures each piece aligns perfectly with the mold and stitching process.

- Reduces waste and speeds up assembly by simplifying later steps.

- High-precision cutting contributes to clean edges, symmetrical shapes, and a professional final look.

4. Pre-Heating the EVA Sheets

Preparing the Material for Thermoforming

- The pre-cut pieces are place into pre-heating equipment to soften the EVA.

- Pre-heating allows the EVA sheets to become more pliable and easier to mold.

- This ensures even heat distribution and prevents cracks or inconsistencies during forming.

- Proper pre-heating results in stronger and smoother molded shells.

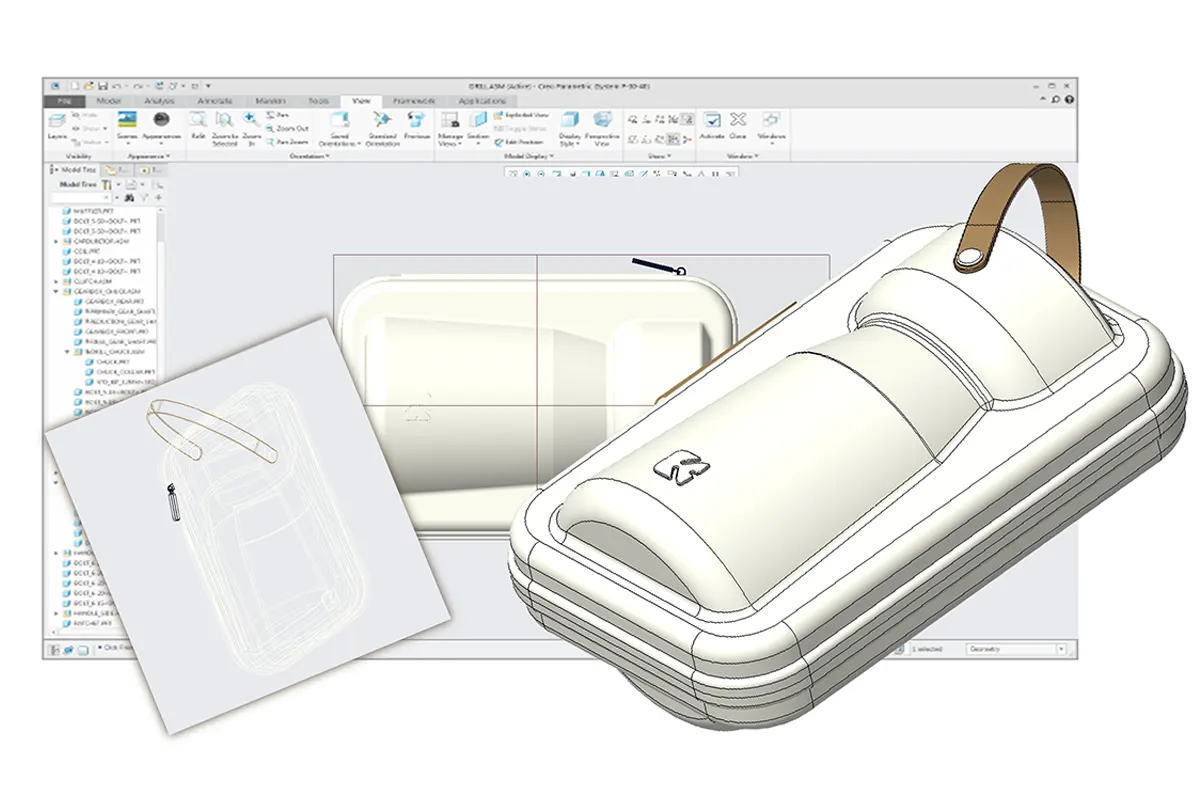

5. Thermoforming / Compression Molding

The Core Step of EVA Case Manufacturing

- The softened EVA sheets are placed into a pre-designed aluminum mold.

- A hydraulic or automotive-grade molding machine applies heat and pressure.

- The EVA expands and conforms to the mold, creating the exact 3D shape of the case.

- Once cooled, the molded part becomes rigid, lightweight, and shock-resistant.

Why Compression Molded Foam Is Ideal

- Delivers a sleek, semi-rigid shell that combines flexibility with strength.

- Allows for customized shapes that perfectly match your product’s dimensions.

- Offers excellent shock absorption for electronics, tools, and medical devices.

- Creates a premium, uniform appearance that elevates brand quality.

6. Trimming & Shell Refinement

Cleaning Up the Molded Shell

- After thermoforming, any excess EVA around the edges is removed using a die-cut machine.

- This ensures the case shell looks clean, symmetrical, and professional.

- Fine trimming helps both halves of the case (top and bottom) align perfectly during stitching.

- This stage affects the overall appearance and structural stability of the finished product.

7. Stitching, Assembly & Structure Construction

Joining Molded Pieces Into a Finished Case

- Skilled craftsmen stitch the molded shells together with fabric edges, zippers, and reinforcement layers.

- Heavy-duty sewing machines ensure strong seams that withstand frequent opening and closing.

- Additional panels, pockets, mesh layers, or elastic straps may be added inside the case.

- This step transforms the molded shell into a functional, stylish custom EVA case.

Importance of Professional Stitching

- Prevents tearing and ensures long-term durability.

- Guarantees smooth zipper operation and case alignment.

- Enhances structural integrity and carrying comfort.

8. Final Inspection & Quality Assurance

- Every single EVA case undergoes a full visual and physical inspection.

- Zippers, seams, fabric surfaces, molded shapes, and logos are checked for defects.

- Any imperfections are repaired or reworked immediately.

- Strict QC ensures that customers receive consistent, reliable cases with minimal failure rates.

9. Packaging & Shipment Preparation

Professional Export-Level Packaging

- Once the inspection is complete, cases are carefully packaged in protective cartons.

- Packaging prevents deformation during transport and ensures clean presentation.

- Bulk orders are palletized and stretch-wrapped to avoid damage in transit.

- Customers can expect their EVA cases to arrive in perfect condition, ready for sale or product assembly.

Conclusion: A Smarter Way to Build Better EVA Cases

The manufacturing process of an EVA case is an elegant combination of engineering, material selection, craftsmanship, and brand customization. From raw material sourcing and precision cutting to lamination, molding, stitching, and final inspection, each step contributes to the durability, appearance, and performance of a custom EVA case.

Partnering with an experienced case manufacturer ensures your product receives the right balance of protection, style, and customization. Whether your brand needs lightweight travel cases, premium electronics kits, or high-performance tool protection, the right manufacturing process delivers results that stand out.