Чехлы из ЭВА стали одним из самых популярных защитных упаковочных решений для бытовой электроники., медицинские устройства, инструменты, косметическое оборудование, и продукты для образа жизни. Их легкий, но прочный дизайн обеспечивает идеальный баланс между функциональностью и эстетикой, что делает их любимым выбором для брендов, которым нужна защита, не жертвуя при этом стилем..

Независимо от того, новичок ли вы в корпусах EVA или ищете их для своей следующей линейки продуктов., это руководство проведет вас через все, что вам нужно знать: что такое материал ЭВА, как оформляются дела, почему отрасли полагаются на них, и как выбрать дизайн, соответствующий вашим потребностям. Давайте окунемся в мир ЭВА и выясним, почему этот материал меняет современную упаковку..

Что такое Ева (Этилвинилацетат)?

ЭВА означает этилвинилацетат., гибкий, амортизирующий полимер, широко используемый в потребительских и промышленных товарах.. Он известен своей мягкой, запах резины & чувство и превосходная устойчивость.

Ключевые характеристики EVA

- Мягкий и гибкий: ЭВА гнется, не растрескиваясь., что делает его идеальным для формованных защитных чехлов.

- Высокая амортизирующая способность: Пенистая структура распределяет энергию удара., защитные устройства и инструменты.

- Легкий и долговечный: Обеспечивает надежную защиту при минимальном весе., улучшение портативности.

- Водостойкий: ЭВА устойчив к влаге и не разрушается под воздействием влаги..

- Нетоксичный и безопасный: EVA не содержит BPA или вредных химикатов., что делает его пригодным для медицинских и детских товаров.

Почему EVA идеален для производства корпусов

EVA обеспечивает уникальное сочетание производительности и универсальности дизайна..

Преимущества производства корпусов

- Термоформуемая структура позволяет производителям создавать нестандартные формы и фирменные контуры.

- Совместим с текстильной ламинацией., возможность гладкой отделки, такой как нейлон, PU кожа, или полиэстер.

- Твердая, но полужесткая оболочка обеспечивает надежную защиту, сохраняя при этом легкий профиль.

- Поддержка индивидуальных интерьеров., например, пенопластовые вставки или сетчатые карманы для организации вещей..

- Длительная долговечность, снижение необходимости замены и снижение воздействия на окружающую среду.

Для чего используются чехлы из ЭВА?

1. Электроника & Технические аксессуары

Чехлы из ЭВА обеспечивают надежную и стильную защиту хрупких электронных устройств..

- Камеры, дроны, и боевое снаряжение требующие сильной амортизации.

- Наушники, наушники, и пауэрбанки нужен легкий, портативное хранилище.

- Игровые устройства и контроллеры, которым выгодны интерьеры, изготовленные по индивидуальному заказу.

- Аксессуары и зарядные устройства для ноутбуков, часто упаковывается в удобные для путешествий чехлы из этиленвинилацетата..

2. Инструменты & Промышленное оборудование

Почему инструменты полагаются на EVA: Корпуса eva для инструментов являются одними из наиболее распространенных., благодаря повышенной долговечности.

- Полужесткие корпуса защищают от падений., вибрация, и грубое обращение.

- Специальный пенопласт с вырезами надежно удерживает инструменты на месте..

- Водостойкие поверхности защищают металлические инструменты от ржавчины..

- Легкая конструкция повышает мобильность для полевых технических специалистов..

3. Медицинский & Медицинские устройства

Преимущества безопасности и гигиены EVA делают его идеальным для продуктов здравоохранения..

Типичные случаи использования

- Стетоскопы, мониторы артериального давления, и диагностические наборы требующие стабильной организации.

- Портативные медицинские приборы, особенно во время путешествий или хранения в аптечках.

- Чувствительные измерительные приборы, защищен специальными пенопластовыми вставками.

- Очищаемые поверхности, обеспечение легкой санитарии.

4. Красота, Оздоровление & Личная гигиена

Упаковка из ЭВА улучшает внешний вид, обеспечивая при этом функциональную защиту..

- Инструменты для укладки волос например, выпрямители или триммеры.

- Устройства для ухода за кожей например, светодиодные косметические инструменты или микротоковые устройства..

- Наборы визажиста требующая раздробленной организации.

- Премиальные подарочные наборы для этого нужен гладкий, современная эстетика.

5. Открытый, Виды спорта & Туристическое снаряжение

Легкий вес, прочный, и устойчивость к атмосферным воздействиям — EVA поддерживает активный образ жизни.

- Аптечки первой помощи предназначен для использования на открытом воздухе.

- Аксессуары для походов и кемпинга которым нужна защита от пыли и ударов.

- Органайзеры для спортивного снаряжения, например чехлы для очков или датчиков.

- Организаторы путешествий, идеально подходит для туалетных принадлежностей и электроники.

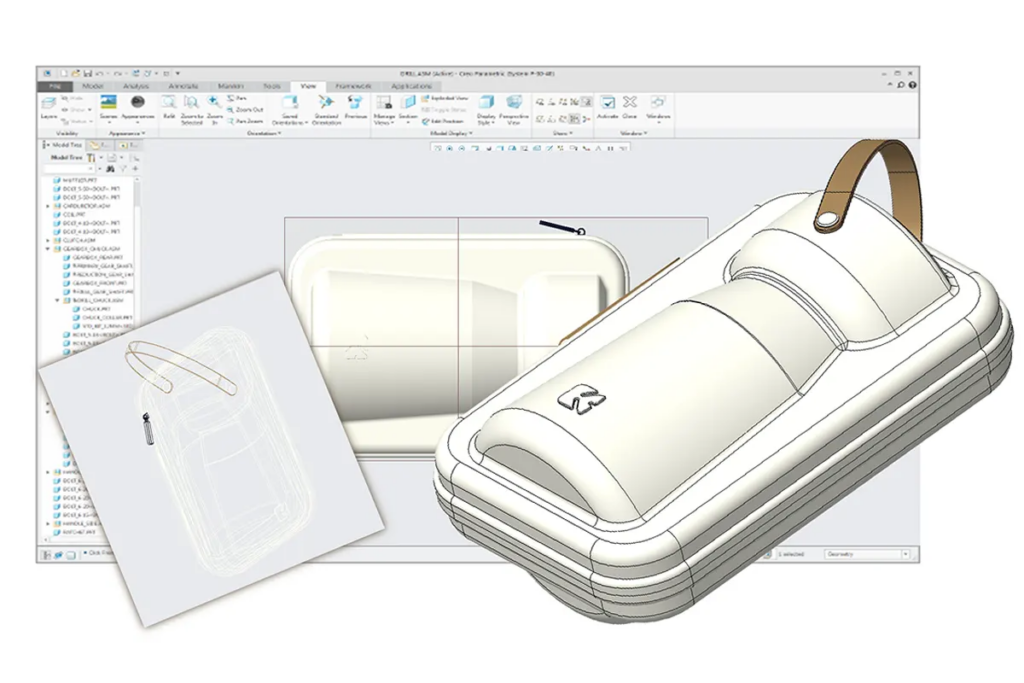

Как изготавливаются корпуса из ЭВА (Пошаговый процесс изготовления)

1. Выбор материала & Подготовка

Производство начинается с выбора подходящего пенопласта EVA и внешних тканей..

- Выбор плотности и толщины ЭВА исходя из требований долговечности.

- Выбор тканевого покрытия, например, нейлон, полиэстер, или искусственная кожа.

- Подготовка цветной и фактурной отделки. чтобы соответствовать фирменному стилю.

- Обеспечение совместимости материалов для ламинирования и формования.

2. Ламинирование листов ЭВА

Лист ЭВА скрепляется с выбранной тканью посредством тепла и давления..

- Создает гладкую внешнюю поверхность для брендинга и эстетики.

- Повышает долговечность, помогает противостоять царапинам и потертостям.

- Укрепляет скорлупу, придание корпусу более прочной структуры.

- Позволяет использовать пользовательские текстуры как матовый, глянцевый, или отделка из углеродного волокна.

3. Компрессионное формование

Ламинированный ЭВА нагревается и помещается в формы для придания формы корпусу..

- Обеспечивает точные контуры для индивидуального дизайна и форм для конкретного продукта.

- Поддерживает тисненые или тисненые логотипы, повышение узнаваемости бренда.

- Обеспечивает эргономичную форму, повышение комфорта пользователя и мобильности.

- Обеспечивает равномерную толщину оболочки. для последовательной защиты.

4. Дизайн интерьера & Резка пенопластовой вставки

Внутри корпуса, органайзеры добавлены для обеспечения безопасности предметов.

Варианты персонализации интерьера

- Вырезанные вставки из пенополиуретана или этиленвинилацетата. адаптированный к форме продукта.

- Сетчатые карманы для кабелей или аксессуаров.

- Эластичные ремни удерживать предметы на месте.

- Водостойкие подкладки для дополнительной защиты.

5. Шить & Сборка

Молнии, ручки, и аксессуары добавлены.

- Вшивание молнии к формованной оболочке из ЭВА.

- Крепление ручек, ремни, или резиновые ручки для лучшего удобства использования.

- Добавляем элементы брендинга например нашивки или резиновые логотипы.

- Проверка качества для обеспечения безупречных швов и структуры.

6. Заключительная проверка

Каждый чехол проходит проверку качества перед отправкой.

- Ударопрочность и испытание на твердость.

- Проверка выравнивания и прочности молнии.

- Внутренняя подгонка, обеспечение соответствия пенопластовых вставок размерам изделия.

- Общая эстетика, включая постоянство цвета и точность брендинга.

Как правильно выбрать корпус EVA для нужд вашей отрасли

Выбор подходящего поставщика чехлов из ЭВА зависит от типа вашего продукта., отраслевые стандарты, Требования к долговечности, и цели брендинга.

1. Определите необходимый уровень защиты

Разные продукты требуют разной прочности конструкции..

- Вам нужен мягкий, полужесткий, или твердая оболочка из ЭВА?

- Требует ли продукт амортизации?, водонепроницаемость, или защита от пыли?

- Будет ли чехол использоваться в помещении, на открытом воздухе, или во время путешествия?

- Нужна ли тепловая защита для чувствительной электроники?

2. Оцените требования к внутренней организации

Внутренняя часть корпуса EVA так же важна, как и внешняя..

- Индивидуальные пенопластовые вставки для хрупких или дорогостоящих устройств.

- Сетчатые карманы или эластичные ремни. для мелких аксессуаров.

- Флэт против. контурные интерьеры, в зависимости от формы изделия.

- Съемные вставки из пенопласта. для многоразового хранения.

3. Выбирайте правильные материалы и внешний дизайн

Имидж вашего бренда и позиционирование продукта определяют эстетику.

- Тип ткани: нейлон для долговечности, Искусственная кожа для превосходного вида.

- Цветовая палитра в соответствии с брендингом.

- Варианты логотипа: тиснение, печать, или металлические значки.

- Текстуры поверхности от гладких моделей до моделей из углеродного волокна.

4. Учитывайте эргономику и удобство использования

Ваши конечные пользователи должны найти этот чехол удобным и комфортным в использовании..

- Легкая конструкция для мобильности.

- Эргономичные ручки для комфортного ношения.

- Гладкий, прочные молнии для многократного использования.

- Компактные формы оптимизирован для путешествий или хранения.

5. Работайте с профессиональным производителем корпусов из ЭВА

Партнерство с опытным производителем кейсов eva обеспечивает лучшее качество., настройка, и производительность.

- Доступ к профессиональным формам и оборудованию..

- Более высокая согласованность при больших производственных циклах.

- Поддержка структурного проектирования и инжиниринга.

- Способность соответствовать отраслевым стандартам (медицинский, аэрокосмический, промышленный).

Часто задаваемые вопросы о чехлах EVA

1. Для чего обычно используются корпуса EVA?

Корпуса из ЭВА используются в электронике., инструменты, медицинские устройства, косметические наборы, Наружное снаряжение, и подарочные наборы премиум-класса благодаря своей долговечности, шоковой поглощение, и возможности настройки.

2. Как сделать корпус из ЭВА?

Корпуса из ЭВА производятся методом ламинирования., компрессионное формование, персонализация интерьера, шитье, и окончательная проверка. Каждый шаг обеспечивает долговечность, соответствовать, и премиальный внешний вид.

3. Не токсичен ли ЭВА??

Да, ЭВА не токсичен., Без BPA, безопасный материал, широко используемый в медицине., потребитель, и детские товары.

Заключение

Чехлы из ЭВА обеспечивают идеальный баланс долговечности., стиль, и практичность, что делает их одним из самых универсальных решений для защитной упаковки на сегодняшний день.. Нужна ли вам индивидуальная защита электроники, Медицинское оборудование, инструменты, или косметические устройства, EVA обеспечивает высокую ударопрочность и превосходный внешний вид, который подчеркивает ваш бренд..

Если вам нужны полностью персонализированные решения EVA, предназначенные для повышения производительности и воздействия на брендинг, сотрудничество с профессиональным производитель футляров eva это самый разумный выбор. При правильном сочетании материалов, структура, и внутренняя планировка, ваш кейс EVA может стать мощным расширением вашего продукта и качества обслуживания клиентов..