Practical & Creative Custom EVA Case Inspiration

EVA Case Manufacturing Process

Discover How Your Case is Made

Dive into our video and witness firsthand how our skilled workers transform raw materials into a masterpiece. Click now to embark on this exploration of our brief manufacturing process.

Custom EVA Case Overview

Style and Substance in Perfect Harmony

Want to make your brand stand out? KinFish Case has you covered with custom EVA carrying cases that are both stylish and practical.

Our team of experienced designers is constantly pushing the boundaries of custom EVA carrying case design, developing unique solutions that align with your brand and product needs.

With our focus on quality and attention to detail, we create custom carrying cases that not only look great, but also provide superior protection for your products. Trust KinFish Case to deliver cutting-edge custom EVA carrying cases that showcase the value and quality of your brand.

Discover EVA Case Solutions for Your Specific Market

Customize EVA cases that are designed to provide superior protection for your items while enhancing your unique brand image.

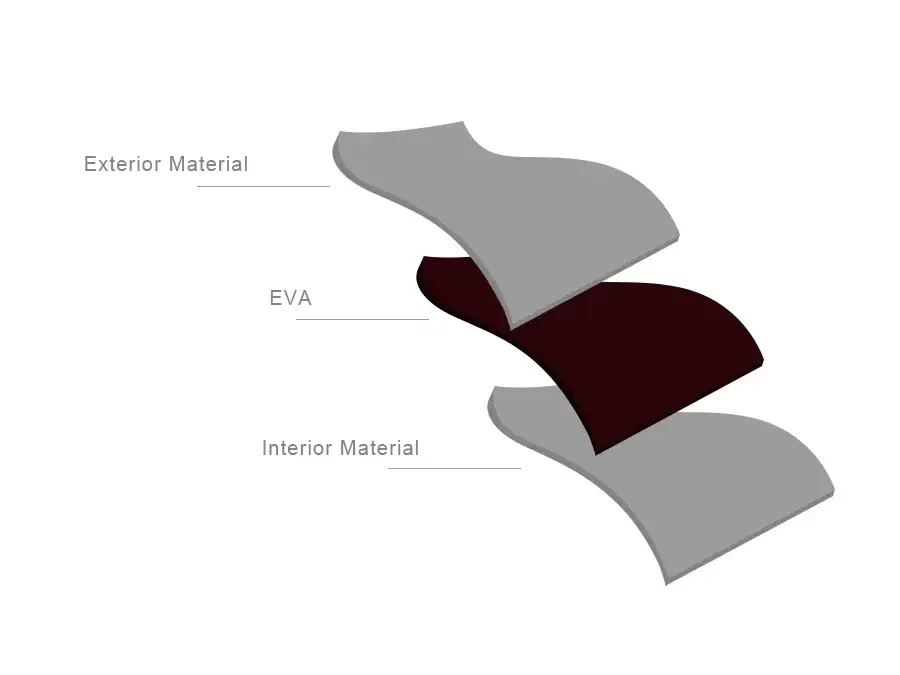

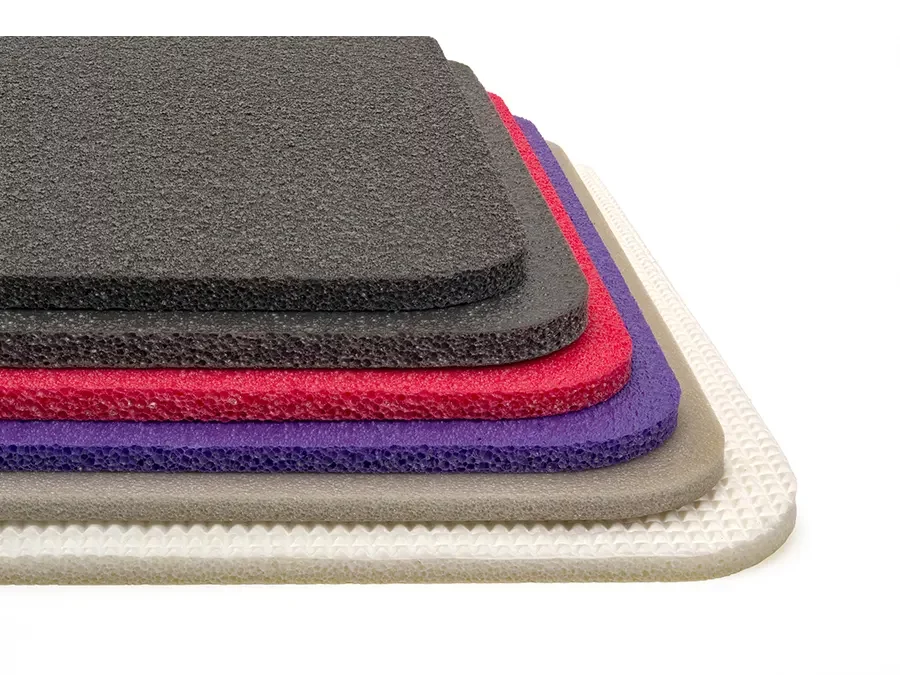

EVA Shell Structure

So what is EVA?

EVA (Ethylene-Vinyl Acetate) is a versatile copolymer made from ethylene and vinyl acetate. It has a wide range of common applications, including in shoe wear and case manufacturing.

Normally, an EVA shell consists of three layers, exterior material, middle layer EVA, and interior material. One of the most notable characteristics of EVA is its ability to be formed into durable yet soft-to-the-touch “hard shell” cases.

Unlike traditional plastic cases, EVA cases are less likely to crack or break. This makes them an ideal choice for protecting sensitive or delicate items.

A Sleek Appearance Does Mean Something

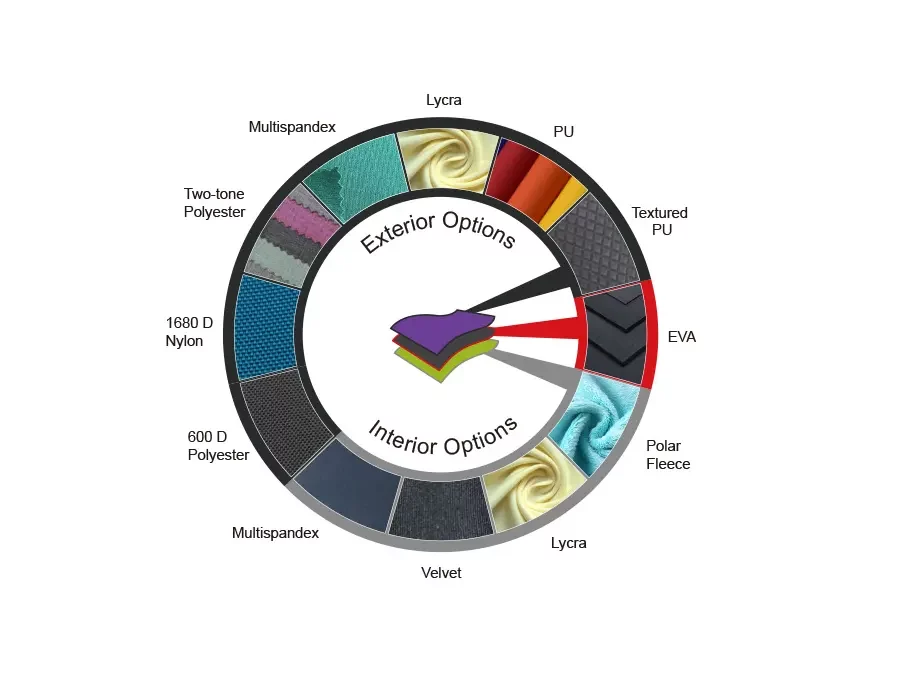

Exterior & Interior Material Options

A good apperance speaks volumes about a brand’s personality, and that’s why choosing the unique exterior and interior materials to build your case is crucial.

We offer a wide range of exterior materials for you to choose from, including multispandex, 600D polyester, 1680D nylon, PU, and more. Additionally, we provide a plethora of interior options that enhance the functional features of the cases.

Each of the materials has its own advantages and disavantages. If you were to compare the differences, such as price and performance, by yourself, it would be quite time-consuming.

But don’t worry, we’ve got you covered! Just inform us about your specific requirements, and we will help you find the best option for your needs.

Beyond the Surface

Foam Insert Options

We offer a wide range of foam material options, including custom EVA foam, sponge foam, EPE foam, and more. Be it simple or complex, each insert can be tailored to meet your unique needs. Let us help you create the perfect foam insert solution for your business needs.

Interior Pocket Designs

Commonly seen pocket designs are showcased here. We specialize in creating unique and practical EVA cases tailored to your specific product type and functional requirements. If you’re interested, please don’t hesitate to contact us for more customization options.

Folded Pocket

Flap Pocket with Velcro Strap

Mesh Pocket

Mesh Pocket with Zipper

Logo Styles

How would like to present your logo on your custom EVA cases? A variety of techniques are available to satisfy your needs, such as embossing, debossing, silk screen printing, and more. The materials for displaying your logo can also be chosen, including rubber, metal, fabric, and others.

PMS Color Match

Based on your brand style, whether it’s bold or subtle, we excel at pairing the most suitable colors to showcase and represent your brand image. Any color is possible!

Branding Capabilities

A fantastic logo can deliver a powerful message: This is who we are. It’s tangible, which represents your identity and significance.

Using various techniques such as color matching, stitching, and other manual operations, our veteran designers and skilled craftsmen work together to bring your logo to life. Let us help you enhance your brand image.

Limitless Accessory Options

There is a portfolio of accessories for your selections. Every detail can be customized to visualize and improve your brand recognition.

Need More Details on Customizations?

For a more comprehensive look at our customization options, be sure to check out the KinFish Case Custom Book. It’s your go-to guide for all the details you need to create the perfect custom EVA case.

And if you still have questions, don’t hesitate to contact us – we’re always happy to help.

Explore What Interesting & Unique EVA Cases We have Completed

Learn About Our Custom EVA Case Cooperative Process

Consultation & Discovery

Hola! We’re expecting you. Let’s get to know a little bit about each other.

To better understand your unique needs for the EVA case, we can always schedule a video call.

This allows us a more tailored and efficient consultation – we can discuss the case’s purpose, size, shape, materials, and other necessary details like face to face. By this, we can we design and manufacture a product that meets your specific requirements and exceeds your expectations.

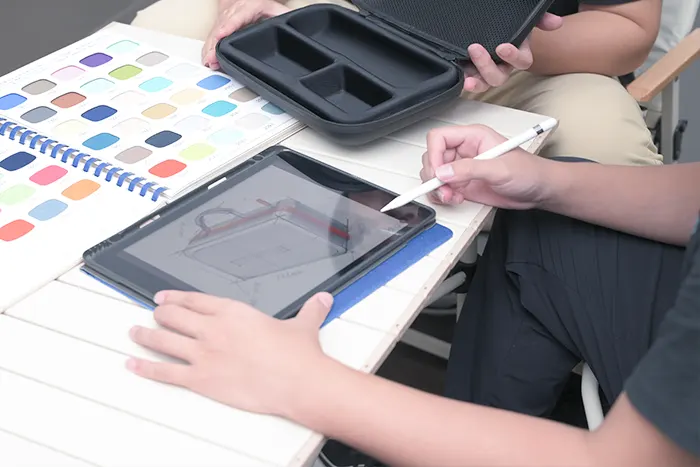

Getting Ready to Design

Hold on, don’t rush yet. We just know each other.

Before we start designing, we may need to sign a non-disclosure agreement(NDA) to protect each of our confidential information.

We create simple drawings and 2D renderings of the case based on the information gathered during the discovery phase. This helps you visualize the product and make any necessary changes before we proceed to the 3D model.

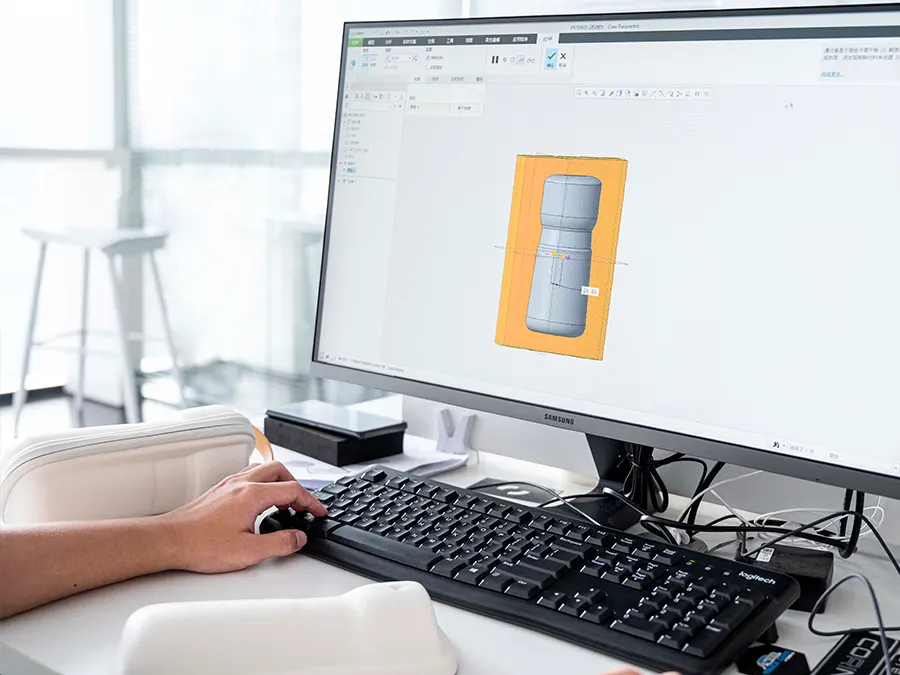

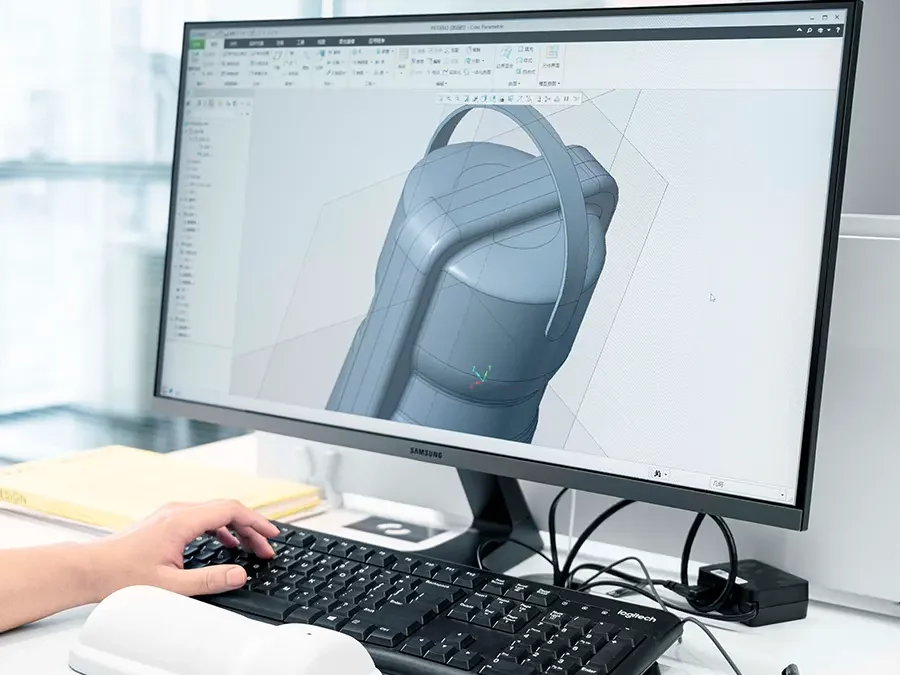

Presentation

Now I guess it’s the phase we both agree on something.

Our team creates a detailed 3D model of the EVA case. By checking the 3D model, you can make any final changes before we move on to the tooling phase

We offer free design services and aim to provide the initial design within 2 days.

Tooling

Now let’s make it happen.

We create the tooling necessary to shape the EVA case. Our team ensures that the tooling meets our high standards for precision and durability. In 5 to 7 days, you will meet it.

Prototype

Ready to meet our artwork?

We begin your custom molded case building and sample production. This allows us to create a prototype of the EVA case and test it for fit, functionality, and durability. If necessary, we make any adjustments before proceeding to mass production.

Mass Production

Woah! There are so many of them.

Once the prototype is approved, we move on to the manufacturing process. Our experienced workers will carefully produce your EVA cases using a range of techniques, including laminating, cutting, thermoforming, stitching, trimming, etc. High-quality materials and state-of-the-art machinery ensure precision and durability.

From start to finish, we closely monitor each step of the manufacturing process to ensure the quality of your products.

100% Thorough Inspection

Attention please, none of them gets to escape.

A rigorous inspection and testing process, from appearance to the smallest accessories on the inside or outside, will be conducted to ensure that each custom EVA case meets our standards for quality and functionality. By 100% inspection, we really mean it.

Delivery

Voila! You got them.

For bulk production, it takes around one month for you to receive your custom EVA cases. We understand that timely delivery is critical, and we’ll work to ensure that you receive your cases on time and in good condition. We’re committed to providing excellent customer service and support throughout the entire process.

Elevate your brand with Custom EVA Cases

Check out the Kinfish Case Blog to make better informed decisions.

How to Custom EVA Cases for Your Product?

Ever wondered how to make your product stand out while keeping it safe and secure? Custom EVA cases are the ultimate solution. These cases combine durability, style, and practicality to ...