When it comes to choosing the right material for products ranging from shoes to protective cases, EVA and PVC often come up as the top contenders. Both materials have unique properties, but understanding their strengths, limitations, and typical applications is essential for manufacturers and consumers alike. Whether you are a case manufacturer or just curious about the differences, this guide will help you make an informed decision.

| Feature / Property | EVA (Ethylene Vinyl Acetate) | PVC (Polyvinyl Chloride) |

| Flexibility | Highly flexible, soft, cushioning | Moderate to rigid, less flexible |

| Weight | Lightweight | Heavier |

| Durability | Durable but can compress over time | Very durable, strong |

| Toxicity / Safety | Less toxic, skin-safe | Can release harmful chemicals (phthalates) |

| Water Resistance | Excellent, can be fully waterproof | Water-resistant but may absorb moisture over time |

| UV Resistance | Good, resistant to UV degradation | Moderate, may degrade under prolonged UV |

| Cost | Slightly more expensive | Cost-effective, cheaper for mass production |

| Applications | Shoe soles, sports mats, protective cases, water shoes | Pipes, flooring, rigid packaging, inflatables |

| Environmental Impact | Easier to recycle, less harmful to environment | Harder to recycle, less eco-friendly |

What Are EVA and PVC?

EVA: A Flexible and Lightweight Material

- Soft and Cushioning

EVA (Ethylene Vinyl Acetate) is prized for its softness and flexibility, making it ideal for applications where comfort and impact absorption are important, such as shoe soles.

- Lightweight

Its low density ensures that products made with EVA remain light and portable, which is particularly valuable for wearable items and portable protective cases.

- Skin-Safe

EVA is generally less toxic than PVC, meaning it is safer for long-term skin contact.

PVC: A Strong and Durable Plastic

- Rigid and Sturdy

PVC (Polyvinyl Chloride) offers structural strength, making it suitable for products that require durability, like flooring or packaging.

- Versatile Uses

PVC can be manufactured in both flexible and rigid forms, which broadens its range of applications.

- Cost-Effective

It is often cheaper than EVA, especially in industrial-scale production.

EVA VS PVC: Key Differences

Flexibility and Comfort

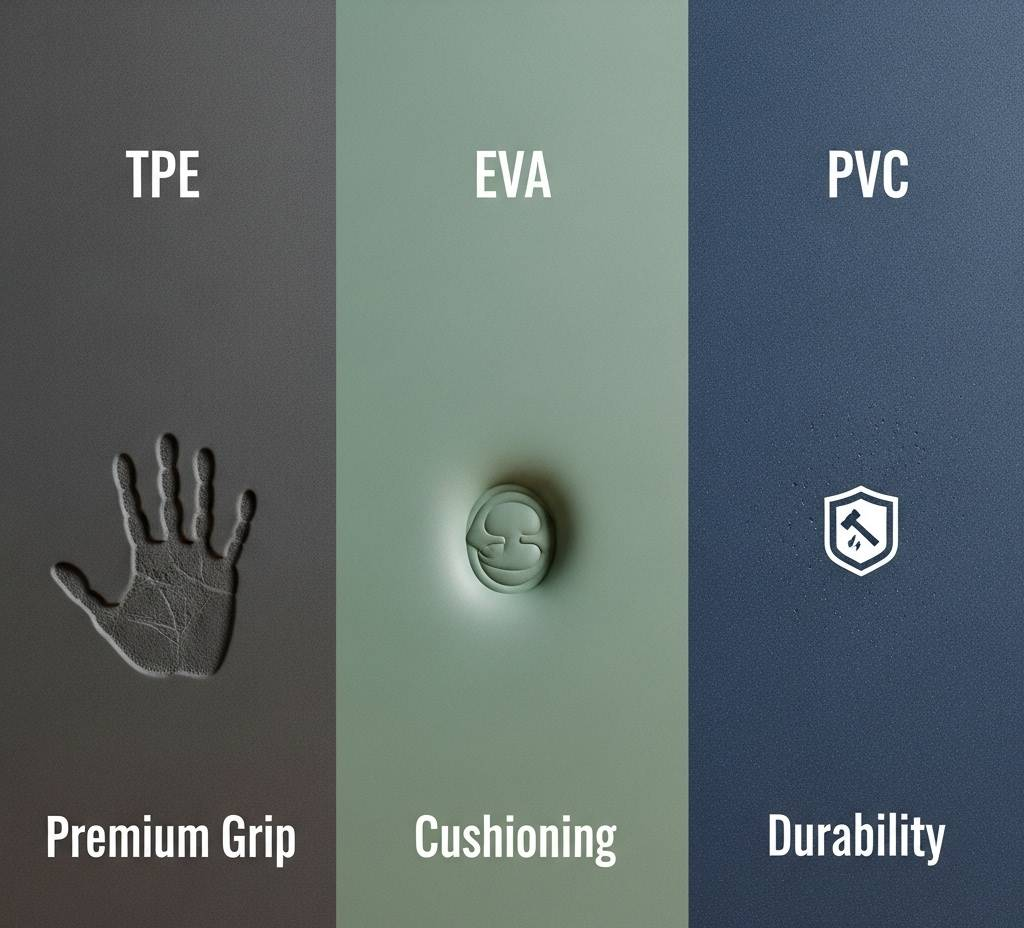

- EVA Material vs PVC: EVA is highly flexible and cushioning, whereas PVC is stiffer and less forgiving under pressure.

- Applications Matter: For shoe soles, yoga mats, or soft protective cases, EVA’s flexibility provides comfort and shock absorption. PVC, in contrast, is more suitable for rigid items like panels or packaging containers.

Toxicity and Safety

- EVA is Safer: EVA is considered less toxic and is generally safe for consumer products that touch skin.

- PVC Concerns: Some PVC formulations release harmful chemicals such as phthalates, making them less suitable for wearable products.

- Environmental Impact: EVA is easier to recycle in many cases and has fewer environmental concerns than traditional PVC.

Water Resistance

- EVA Waterproofing: EVA can be 100% waterproof when molded or sealed, which is why it is popular in water shoes and waterproof cases.

- PVC Resistance: PVC is water-resistant but may absorb moisture in certain forms or when subjected to prolonged exposure.

- Practical Implications: For outdoor gear or waterproof packaging, EVA often outperforms PVC in long-term water resistance.

Pros and Cons of EVA

Advantages of EVA

- Lightweight and Portable: Ideal for shoes, mats, and cases that need to be carried or worn comfortably.

- Shock Absorption: Protects feet, equipment, or packaged items from impacts.

- Less Toxic: Safe for prolonged contact with skin.

- Water and UV Resistance: Maintains performance under exposure to sunlight or moisture.

Disadvantages of EVA

- Heat Sensitivity: Can deform under high heat or prolonged compression.

- Higher Cost: May be more expensive than PVC in some applications, especially in large-scale manufacturing.

- Compression Over Time: Over years of use, EVA may gradually lose its cushioning effect.

Pros and Cons of PVC

Advantages of PVC

- Durable and Strong: Suitable for products that require high structural integrity.

- Cost-Efficient: Often cheaper than EVA, making it ideal for large-scale or industrial applications.

- Versatile: Can be manufactured in both flexible and rigid forms to suit different needs.

Disadvantages of PVC

- Less Comfortable: Stiffer and less forgiving under pressure compared to EVA.

- Toxicity Risks: Improperly processed PVC can release chemicals harmful to humans and the environment.

- Environmental Concerns: PVC is less eco-friendly and harder to recycle than EVA.

FAQ About EVA VS PVC

What is the difference between EVA and PVC foam?

EVA foam is soft, lightweight, and cushioning, making it ideal for footwear, sports gear, and protective cases. PVC foam is harder, denser, and more rigid, commonly used in construction, flooring, and packaging. In short, EVA emphasizes comfort and flexibility, while PVC emphasizes strength and durability.

Is EVA less toxic than PVC?

Yes. EVA is generally safer for skin contact and is considered less toxic than PVC, which may release chemicals like phthalates if not properly stabilized. This makes EVA the preferred choice for shoes, wearable products, and protective cases.

Is EVA 100% waterproof?

EVA can be fully waterproof when molded or sealed, making it excellent for water shoes, mats, and waterproof cases. PVC is water-resistant, but EVA often provides superior long-term protection against moisture.

Applications of EVA and PVC

EVA Applications

- Footwear: EVA is widely used in shoe soles and insoles (what is eva for shoes).

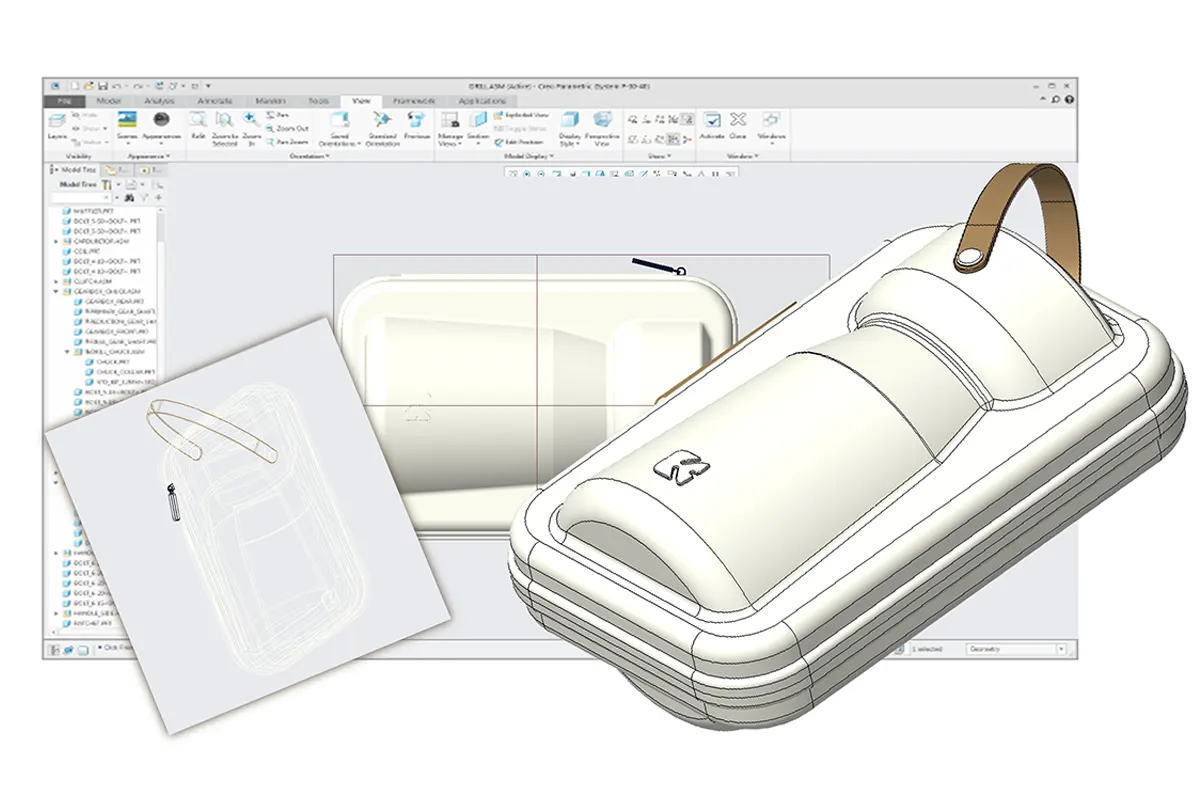

- Protective Cases: Lightweight and shock-absorbing, ideal for electronics, cameras, and other devices (case manufacturer applications).

- Sports and Yoga Mats: Cushioned and comfortable for fitness enthusiasts.

- Waterproof Products: Suitable for water shoes, mats, and outdoor gear.

PVC Applications

- Construction Materials: Pipes, panels, and flooring.

- Packaging: Industrial packaging or rigid containers.

- Inflatables and Toys: Durable and moldable for recreational products.

- Cost-Sensitive Applications: When rigidity is needed but budget is a concern.

Conclusion

Choosing between EVA plastic material and PVC depends on your product’s purpose and performance requirements. If you need lightweight, flexible, and skin-safe materials, EVA is the go-to solution, especially for shoes, protective cases, and waterproof products. On the other hand, if your priority is rigidity, durability, and cost-efficiency, PVC may be the better choice.

Understanding EVA material vs PVC ensures that case manufacturers and product designers make informed decisions that balance performance, safety, and cost. With the right choice, your products can be both practical and long-lasting, while meeting the needs of your customers.

If you’re looking for premium custom EVA cases or expert guidance on choosing the right material for your next project, visit us at kfcase.com. Our team is ready to help you create high-quality, high-performance cases tailored to your brand.