Selecting the right material for your project or product is essential for achieving optimal results. EVA and PVC are two commonly used materials in various industries due to their unique properties and versatility. In this comprehensive guide, we will delve into the characteristics of both EVA and PVC to help you make an informed decision on which is better suited for your specific needs. Let’s take a closer look at what sets these materials apart.

What is EVA Material?

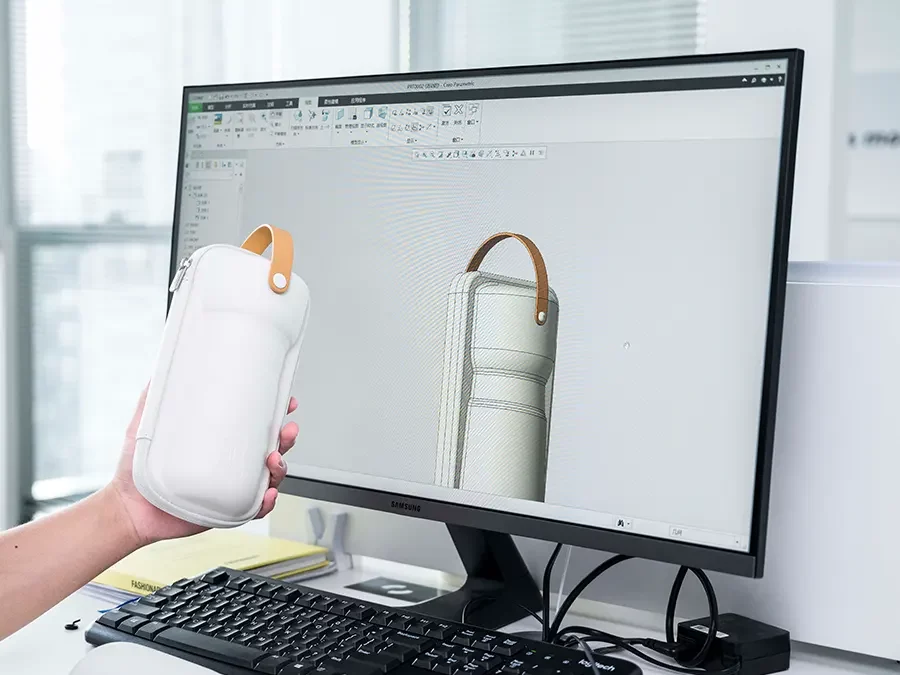

Ethylene-vinyl acetate (EVA) is a copolymer that is known for its lightweight and flexible nature. It is commonly used in the production of foam products, such as shoe soles, sports equipment, and packaging materials to produce EVA case. EVA is also valued for its shock-absorbing capabilities, making it an ideal choice for protective gear and cushioning applications.

What is PVC Material?

Polyvinyl chloride (PVC) is a synthetic plastic polymer that is renowned for its durability and longevity. PVC is highly versatile and can be found in a wide range of products, including pipes, window frames, flooring, and signage. Its water-resistant and flame-retardant properties make it a popular choice for outdoor and construction applications.

Properties of EVA Material

Lightweight and Flexible

One of the standout features of EVA is its lightweight and flexible nature, which makes it easy to work with and comfortable to wear. This quality is particularly beneficial in industries that require products to be lightweight yet durable, such as footwear and padding materials.

Shock-absorbing Capabilities

EVA is prized for its exceptional shock-absorbing capabilities, making it an ideal material for impact-resistant products like helmet liners and protective padding. Its ability to cushion and absorb impact forces helps to reduce the risk of injury in high-impact situations.

Weather-resistant

Another advantage of EVA is its weather-resistant properties, which allow it to withstand exposure to the elements without deteriorating. This makes EVA a reliable choice for outdoor applications where durability and longevity are essential.

Odorless and Non-toxic

EVA is known for being odorless and non-toxic, making it a safe choice for products that come into contact with the skin or food. Its non-toxic nature also makes it environmentally friendly, as it does not release harmful chemicals into the environment.

Properties of PVC Material

Durable and Long-lasting

PVC is renowned for its durability and long-lasting performance, making it a popular choice for products that require high levels of strength and resilience. Its ability to withstand wear and tear over time makes it a cost-effective option for long-term use.

Water-resistant

One of the key advantages of PVC is its water-resistant properties, which make it highly suitable for applications where exposure to moisture is a concern. PVC does not absorb water, making it an ideal choice for outdoor and marine environments.

Flame-retardant

PVC is inherently flame-retardant, meaning that it has a high resistance to ignition and does not propagate flames easily. This makes PVC a preferred material for applications where fire safety is a priority, such as building construction and electrical wiring.

Versatile in Applications

PVC is highly versatile and can be adapted for use in a wide range of applications, from piping and window frames to medical devices and signage. Its versatility and customizable properties make it a go-to material for diverse industries.

EVA vs. PVC, Which Is Better?

When comparing EVA and PVC, several key factors come into play:

Weight and Flexibility

EVA is lighter and more flexible than PVC, making it a preferred choice for applications that require a softer touch and greater comfort.

PVC, on the other hand, is sturdier and less pliable, making it better suited for rigid structures.

Durability and Longevity

PVC is known for its durability and long-lasting performance, making it a reliable choice for products that need to withstand heavy use and harsh conditions.

EVA, while not as durable as PVC, offers excellent shock absorption and cushioning properties.

Resistance to Weather Elements

EVA is weather-resistant and can withstand exposure to the elements without deteriorating, making it suitable for outdoor applications.

PVC is also weather-resistant and can resist moisture and temperature fluctuations, making it a reliable choice for outdoor use.

Heat and Cold Tolerance

PVC has a higher tolerance for heat and cold temperatures compared to EVA, making it suitable for applications that require thermal stability.

EVA may soften or harden in extreme temperatures, which can impact its performance in certain environments.

Cost Comparison

In terms of cost, EVA is generally more affordable than PVC due to its lower production costs. However, PVC’s durability and longevity may offset the initial investment, making it a cost-effective choice in the long run for certain applications.

Applications in Industries

Both EVA and PVC find a wide range of applications across various industries:

EVA Applications

- Footwear: EVA is a popular material for making shoe soles and insoles due to its lightweight and shock-absorbing properties.

- Sports Equipment: EVA is used in the production of sports padding, helmets, mats, and grips for sporting equipment.

- Protective Gear: EVA’s superior shock absorption makes it an ideal material for creating protective gear such as helmet liners and padding for sports and safety equipment.

- Packaging Materials: EVA is also used in the manufacturing of packaging materials, including EVA hard shell cases for electronics, tools, and delicate items.

PVC Applications

- Piping: PVC pipes are widely used in plumbing, irrigation, and drainage systems for their durability, corrosion resistance, and ease of installation.

- Window Frames: PVC is a common material for manufacturing window frames and profiles due to its weather resistance, low maintenance requirements, and energy efficiency.

- Flooring: PVC flooring, including vinyl tiles and vinyl plank flooring, is popular for its durability, water resistance, and wide range of designs.

- Electrical Insulation: PVC is used in electrical applications for cable insulation, wiring, and electrical conduit due to its flame-retardant and insulating properties.

- Signage: PVC sheets and boards are commonly used for indoor and outdoor signage due to their durability, weather resistance, and ease of customization.

EVA vs. PVC, Which to Choose?

When deciding between EVA and PVC for your project or product, consider the following factors:

- If you prioritize lightweight and flexibility, EVA may be the better choice.

- For applications that require durability and longevity, PVC may be more suitable.

- Weather resistance, heat tolerance, and cost considerations should also guide your decision.

Conclusion

In conclusion, both EVA and PVC offer unique properties and benefits that make them valuable materials in various industries. Understanding the key differences between EVA and PVC, such as weight, flexibility, durability, weather resistance, and cost, will help you make an informed decision on which material is better suited for your specific needs. Whether you choose EVA or PVC, both materials provide versatility, performance, and reliability for a wide range of applications.